Case 1C Scaling Time for 1000 Steps for the load ramp

The target time step is reduced to Δttarg = 0.001 increasing the natural frequency for the column and resulting in ca. 1000 steps for the ramp for load case 1.

Data File |

|

*TIME SCALING, TYPE=Optimal, TARGET TIME=1.0E-3 |

The target time step is set to 0.001 so that approximately 1000 steps will be used to simulate the load ramp time of 1.0. |

The results are visualized by plotting the high definition history data for global energy and points output in files mech_001_2d_Case1c_000.hdh and mech_001_2d_Case1c_001.hdh respectively. This data can be pasted into excel workbook mech_001.xls.

Increasing the number of time steps by decreasing the critical time step has two effects:

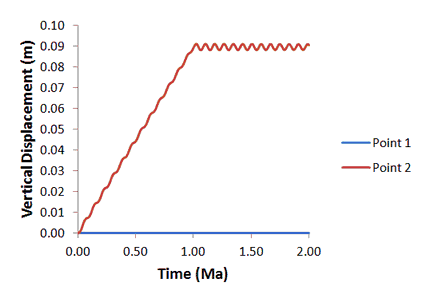

1The solution is much closer to the quasi static target of a linear ramp followed by constant displacement.

2The vibration frequency, which is dependent on the scaled mass, is increased. This is clearly seen in the frequency of the oscillations between time t=1.0 and t=2.0 when the load is constant.

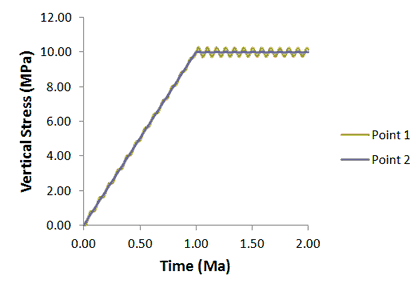

The stress at the base of the column (Point 1) now increases systematically with the stress at Point 2 and much smaller magnitude oscillations occur between time t=1.0 and t=2.0.

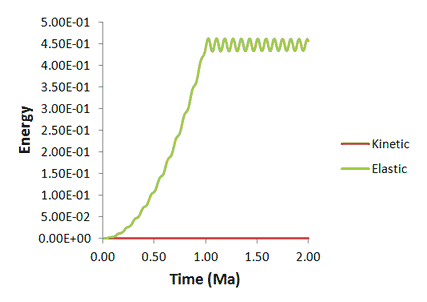

Similarly, the global energy exhibits oscillatory response with higher frequency and lower magnitude between time t=1.0 and t=2.0 than for Case 1B.