Case 4 Case with penetration dependent stiffness

The data files for the project are in directory: Cont_001\Exercises\Case 4\Data. Look for ! TODO text in the datafile and follow the instructions.

In this tutorial exercise the Cont_001_Case1.dat is taken as a template (see Case1 for full description of the data) and the Contact_property is modified so that the penalty stiffness is dependent on the penetration. This has the advantage that allows to decrease the stiffness when the penetration is low and is increased when required. See the data below:

Contact_set

Data File |

|

* Contact_set NUM=1 ! ---------------------------------------- Name "Base-Block" Geometry_sets IDM=2 "Base_top_surface" "Block_base" Algorithm "Penalty" Property_name "Block_friction" Global_update_frequency 1000 Field_factor 0.5 Buffer_factor 1.0

|

1The data is identical to the previous cases

|

Contact_property

Data File |

|

||||||||||||||||||||||||||||

* Contact_property NUM=1 ! ---------------------------------------- Name "Block_friction" Field_dep_stiffness_model 1 Field_dep_stiffness_properties IDM=5 /"Lower stiff Factor"/ 0.1 /"Upper stiff Factor"/ 1.0 /"Lower penetration Factor"/ 0.0 /"Upper penetration Factor"/ 0.2 /"Max. Change Factor"/ 1.002 Compression_model 1 Compression_properties IDM=1 /"Normal Penalty"/ 500 Tangential_model 1 Tangential_properties IDM=1 /"Tangential Penalty"/ 1000

|

1The Field_dep_stiffness_model keyword is added and set equal to 1 (field/penetration dependent stiffness model). 2Five properties are required for the field dependent stiffness model: a.Lower stiffness factor(Fstifflo): scaling factor for the penalty stiffness at lower reference penetration distance dplo = dfield · Fpenlo, where dfield is the field distance and Fpenlo is the lower penetration factor. b.Upper stiffness factor (Fstiffup): scaling factor for the penalty stiffness at upper reference penetration distance dpup = dfield · Fpenup, where dfield is the field distance and Fpenup is the upper penetration factor. c.Lower penetration factor (Fpenlo): multiplication factor for the field distance to calculate the lower reference penetration distance dplo (which is associated to the Lower stiffness). d.Upper penetration factor (Fpenup): multiplication factor for the field distance to calculate the upper reference penetration distance dpup (which is associated to the Upper stiffness). e.Maximum Change Factor: Maximum change factor in stiffness between consecutive time steps. This is used to prevent sudden stiffness changes which can lead to numerical instabilities. 3Note that for penetration distances d so that dpup > d > dplo the scaling factor for the penalty stiffness is calculated by linear interpolation. 4The scaling factor for the penalty stiffness is used to scale the normal penalty, the tangential penalty and the adhesion penalty. 5Apart from the penetration dependent model the rest of the data is unchanged.

Stiffness calculation example

In the present case the field factor in the contact set is set to Ffield=0.5 and the element size to Esize=0.4 m. Therefore the field distance is: dfield = 0.4 m· 0.5 = 0.2 m. The lower penetration factor (Fpenlo) and higher penetration factor (Fpenup) are set to 0.0 and 0.2 respectively. Thus the lower and upper reference penetrations are calculated as: dplo = 0.2 m · 0 = 0 m dpup = 0.2 m · 0.2 = 0.04 m

The normal and tangential penalties are set to 500 MPa and 1000 MPa respectively. The lower (Fstifflo) and upper (Fstiffup) stiffness factors are set to 0.1 and 1.0 respectively. Therefore the effective penalty stiffness for different penetration distances will be:

|

| Results |

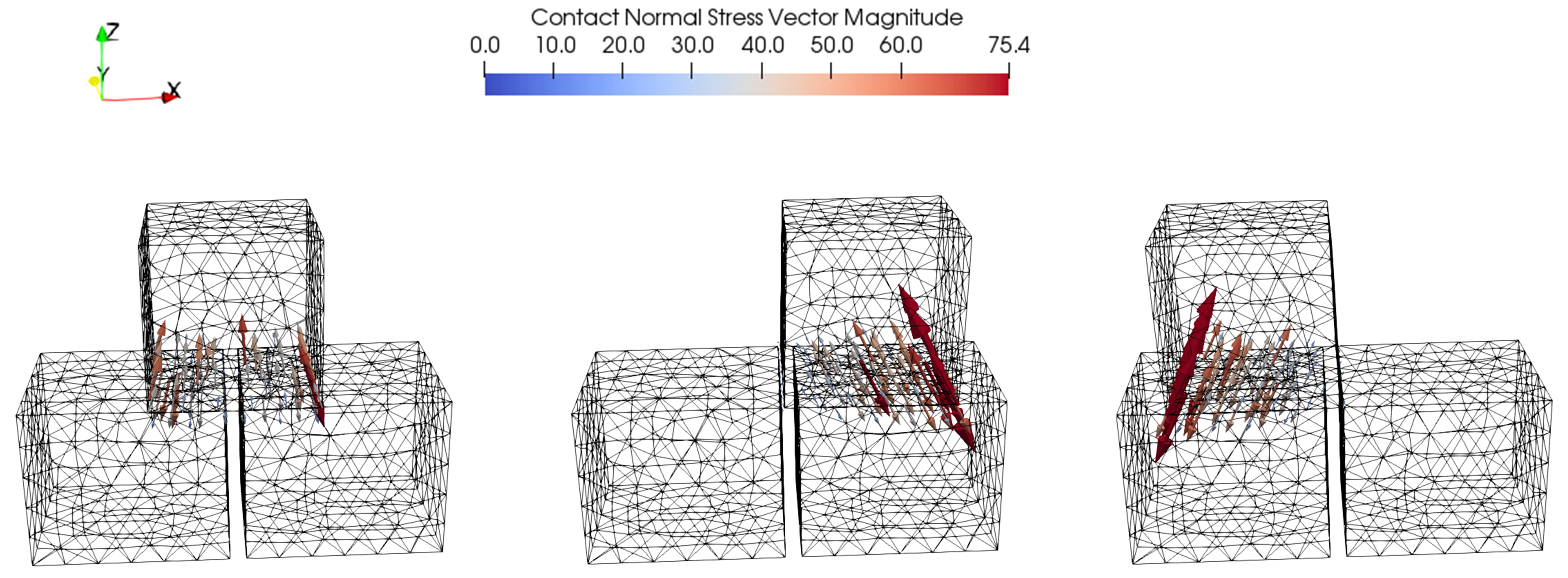

The result files for the project are in directory: Cont_001\Exercises\Case 4\Results. The results are similar as those for case 1.

Glyph plot of contact stress vectors at the end of each stage

|