Case 1C Scaling Time for 1000 Steps

The data file for this exercise is located in directory: mech_001\Exercises\Case1C\Data. Look for ! TODO text in the datafile and follow the instructions.

The target optimal time step is reduced to Δttarg = 0.001 increasing the natural frequency for the column and resulting in ca. 1000 steps for the ramp for load case 1.

Data File |

|

* Time_scaling_factors ! --------------------------------- Optimal_time_step 1.0E-3

|

The target optimal time step is set to 0.001 so that approximately 1000 steps will be used to simulate the load ramp time of 1.0 (so approximately 2000 steps will be used for the entire simulation). |

The results are visualized by plotting the high definition history data for global energy and points output in files mech_001_2d_Case1c_000.hdh and mech_001_2d_Case1c_001.hdh respectively. This data can be pasted into excel workbook mech_001.xls.

Increasing the number of time steps by decreasing the critical time step has two effects:

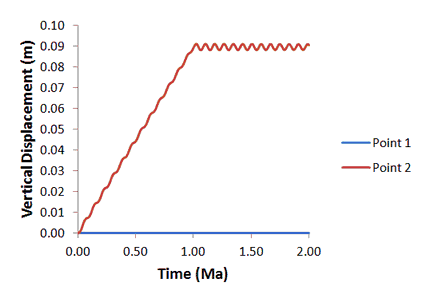

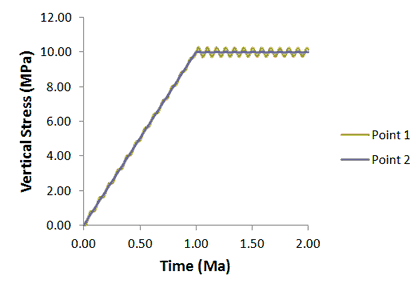

1The solution is much close to the quasi static target of a linear ramp followed by constant displacement.

2The vibration frequency, which is dependent on the scaled mass, is increased. This is clearly seen in the frequency of the oscillations between time t=1.0 and t=2.0 when the load is constant.

The stress at the base of the column (Point 1) now increases systematically with the stress at Point 2 and much smaller magnitude oscillations occur between time t=1.0 and t=2.0.

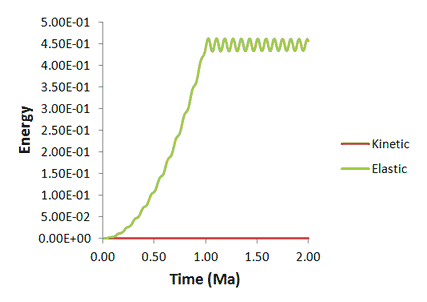

Similarly, the global energy exhibits oscillatory response with higher frequency and lower magnitude between time t=1.0 and t=2.0 than for Case 1B.

The datafile mech_001_2d_Case1c2.dat is provided as an example of usage of Target_number_time_steps withing * Control_data data structure instead of * Time_scaling_factors. The example is set so that a consistent number of time steps for the two cases are used.