Case04 Contact tangential flow conductivity as a function of contact gap

The initial data file for the project is: Cont_002\Case04\Data\Cont_002_Case04.dat.

In this case the contact tangential flow conductivity is defined to be a function of the actual contact gap. This model considers that the contact tangential conductivity is defined as:

![]()

Where ![]() is the contact normal gap and

is the contact normal gap and ![]() is the fluid viscosity.

is the fluid viscosity.

In field scale simulations contact gaps may not be representative of the fault width because:

1) contact gap may arise as a consequence of the fault curvature and mesh size

2) at field scale fault roughness is not accurately represented and fault surfaces are rather smooth and

3) in most field scale situations there is mesh penetration instead of contact gap.

However this model may be applicable to model extensional fractures (e.g. hydraulic fracture) or problems at lab-scale or micro-scale where fracture roughness topology may be properly defined. Hence for this case the geometry, material properties and boundary conditions have been changed to lab-scale with the appropriate units (m, s, Pa).

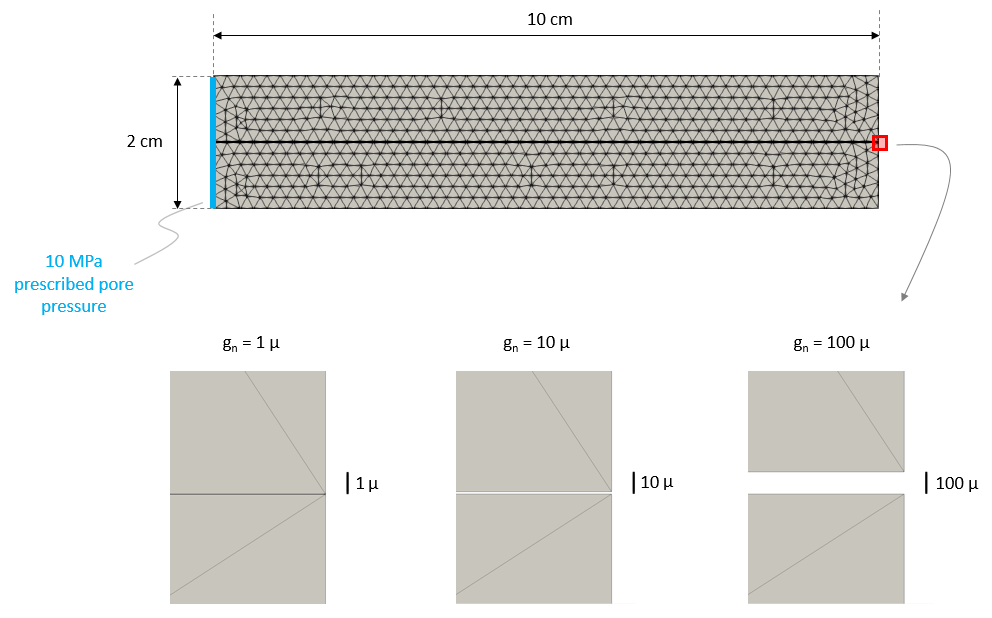

The geometry and conditions are shown below. A rectangular geometry of 10 cm x 2 cm with a horizontal fracture is considered. Three cases are considered with three different contact gaps defined by modifying the corresponding geometry nodal coordinates. Note that in this case temperature flow is not considered as the focus is on the contact flow model.

Model geometry and boundary conditions.

For more information about contact mechanics see Overview of Contact in ParaGeo and for contact data definition see Contact Data.

Contact_property

Data File |

|

* Contact_property NUM=1 ! ---------------------------------------- Name "Sand_contact" Compression_model 1 Compression_properties IDM=1 /Normal Penalty/ 1000E+6 Tangential_model 2 Tangential_properties IDM=2 /Tangential Penalty/ 100E+6 /Friction coefficient/ 0.1 Flow_model_normal 1 Flow_properties_normal IDM=2 /Fluid Cond. (Contact)/ 5E-11 /Fluid Cond. (Filter Cake)/ 5E-11 Flow_model_tangential 4

|

1The Flow_model_tangential is set to 4 (fluid conductivity as a function of contact gap and fluid viscosity). No additional data is required to define contact tangential conductivity.

|

| Results |

The results for the project are in: Cont_002\Case04\Results.

The three cases considered are:

Cont_002_Case04a: Contact gap of 0.1 µm (conductivity of 8.33E-20 m2/Pa/s) Cont_002_Case04b: Contact gap of 1 µm (conductivity of 8.33E-17 m2/Pa/s) Cont_002_Case04c: Contact gap of 10 µm (conductivity of 8.33E-14 m2/Pa/s)

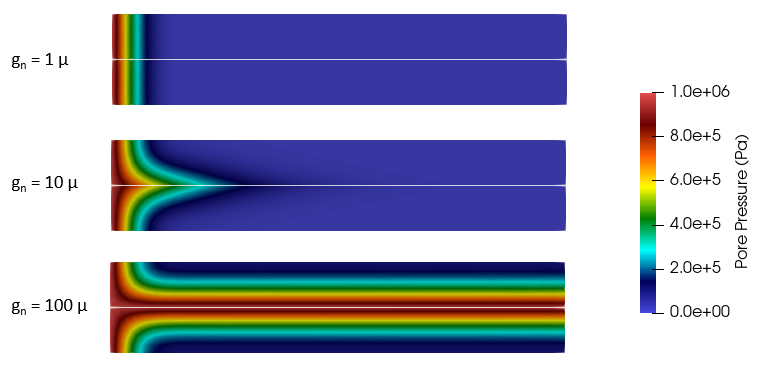

In the three cases 1 MPa of pore pressure was prescribed in the left boundary as an instantaneous load. The simulation time is 3600 s (1 h). The results below show the pore pressure contours at the end of the simulation. It can be seen that as the contact gap increases the contact tangential conductivity also increased, facilitating tangential contact flow. As a result high pore pressure can propagate toward the right model boundary (for Case04c the flow velocity has been enough for the right boundary to reach 1 MPa of pore pressure at the contact surface location).

It can be seen that in case04a (contact gap of 0.1 µm leading to a conductivity of 8.33E-20 m2/Pa/s) the contact conductivity hinders the transfer of pressure towards the right hand boundary as the contact conductivity is lower than that of the matrix ( 1E-18 m2/Pa/s).

Pore pressure contours after one hour (3600 s) for the three cases considered.

|