Case 3 Characterization of Experimental Data (Poroelasticity)

In the previous exercise Linear elasticity with SR4 plasticity was used to simulate a set of experiments performed on weak sandstone samples at different confining pressures. However the experimental data showed a marked poroelastic behaviour (increase in stiffness with increasing confining pressure). The objective of this exercise is to add poroelastic data to the previously calibrated material in order to obtain a better approximation of the behaviour observed in the experimental data. To that end Cam-Clay poroelasticity will be assumed (poroelastic model 1).

The data files for the exercise are in mat_001\Exercises\Case3\Data. Look for ! TODO text in the"mat_001_Case3.mat" material file and follow the instructions. Note that the initial material datafile provided contains the proposed calibration for the material parameters shown in Case2 results section but the present exercise can also be undertaken with the user calibrated parameters.

| Problem description and exercise |

The geometry, initial conditions, boundary conditions and problem definition are identical to Case 1.

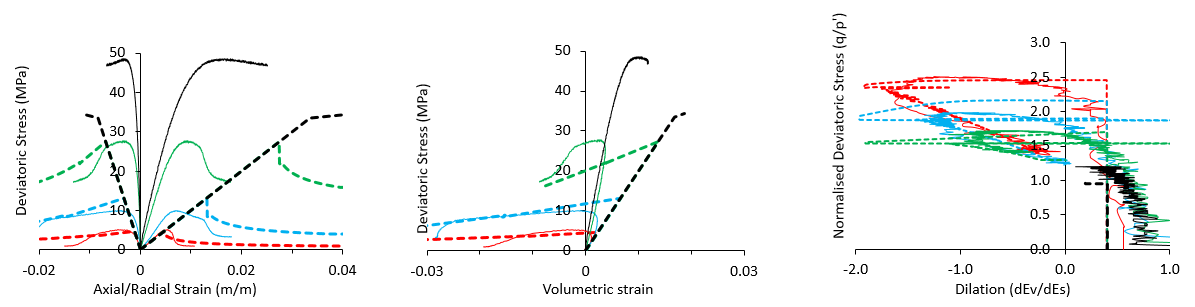

The aim of this exercise is to incorporate Cam Clay poroelasticity to the previously calibrated material in Case2. Such poroelastic law is defined by two input parameters; the reference bulk modulus and kappa according to the following equation:

Where

Note: The aim of this exercise is to represent the gross poroelastic behavior observed in experimental data so that high accuracy in the calibration is not expected. Note that the simulation considers only a single axi-symmetric element and a single surface plasticity model so there may be processes which occurred in the experiments that won't be represented (e.g. gradual transition from elasticity to plasticity due to different yield for the grains and the bonds, strain localisation for over consolidated tests, non-homogeneous strain distribution, etc).

|

The result files for the project are in directory: mat_001\Exercises\Case3\Results. The history results can be pasted into the Excel file mat_001_Case3.xlsm.

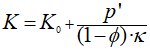

The results shown below are obtained by defining a Cam Clay poroelastic law with K0 = 600 MPa and κ = 0.01. As can be observed the incorporation of the Cam Clay poroelasticity enabled to improve the simulated stiffness for all the tests with different confining pressures.

Results for the present case considering Cam Clay poroelasticity

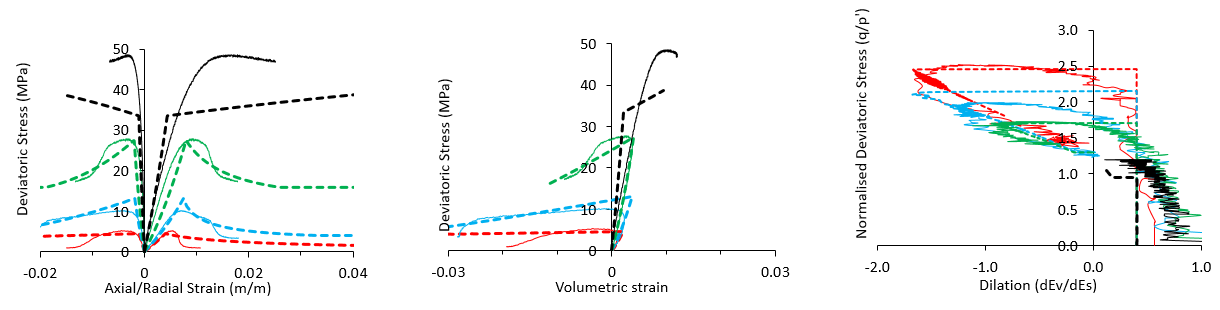

Results for the linear elasticity case illustrated in Case2

|