Case01 procedure and inputs

Here the procedure to define a target normal compaction trend and the data input will be discussed. To that end in Mat_001d/Additional the spreadsheet 00_Material_Master_v02_Ss_Si_Sh_Ca.xlsx is provided to facilitate the visualisation of results and also to provide the suggested input values for the mechanical compaction models following our developed facies-mixture database presented in tutorial Mat_001c_Case02.

The mechanical compaction models use Athy or Schneider input properties, in conjunction with the remaining elastic, poroelastic and plastic input properties, to automatically calculate the corresponding hardening properties for use in the simulation. This is done internally and the user does not require to manipulate the hardening data. However when using the mechanical compaction models the code automatically outputs an .hdh file containing the generated hardening data in a sub-folder named Compaction for each of the materials in the simulation, thus enabling validation of the data in case the user is interested. The .hdh file is named as ModelName_MaterialName.hdh.

The suggested procedure is then as follows:

1.Define all elastic and poroelastic properties

2.Define the plastic properties relative to the yield and flow potential surfaces

3.Define the input values for the Athy or Schneider mechanical compaction trends

4.Define initial estimates for k0 and pc/p' ratio values during uniaxial consolidation (those values are required to compute the hardening data. For more info the user is referred to Mat_001c_Case01 ). The suggested ranges for the initial guess values are 05 - 0.85 for k0 and 1.03 to 1.12 for pc/p' ratio.

5.Run a single element k0 test and check the results in terms of predicted k0 and pc/p'

6.Update those input values in the material if required (see the final figure in Mat_001c_Case01 for a reference in the potential error in the predicted NCT compared to the target)

7.Run a column consolidation model to validate the results

This is demonstrated in the following examples. Note that only the input and output relative to the mechanical compaction models will be discussed. The files for the examples are provided in Mat_001d/Case01/Data. The following cases are undertaken:

•Case01a: Material defined using the Schneider model with optional-related parameters being defined in the data file.

•Case01b: Material defined using the Athy model (equivalent properties to Case01a). Only compulsory data is being defined.

For Case01a two simulation data files are provided:

•Mat_001d_Case01a_k0.dat which simulates a single element k0 test used to correct the initial k0 and pc/p' guess.

•Mat_001d_Case01a_cons.dat which simulates gravity consolidation in an initially 13 km high column over a long time period (hydrostatic pore pressure) to validate the obtained normal compaction trend.

For Case01b the consolidation data file is provided as the properties are equivalent to those in Case01a and we already corrected the initial guess values for k0 and pc/p'.

Case01a

The mechanical compaction data in Mat_001d_Case01a.mat is discussed below.

Data File |

|

* Material_data ! ------------------------------------------- Name "Mech_20_00_80_00" ! ---------------------------------------------- Mech_comp_type 1 ! Schneider Mech_comp_properties IDM=4 /Porosity A/ 0.321 /Porosity B/ 0.321 /Compr. A/ 0.000726 ! 1/m /Compr. B/ 0.000726 ! 1/m Mech_comp_settings IDM=2 /pc to p' rat./ 1.05 /k0/ 0.81 ! ---------------------------------------------- ! Optional mech comp parameters Mech_comp_min_porosity 0.01 Mech_comp_max_depth 8000 Mech_comp_num_points 35

|

1.Mech_comp_model is set to 1 to use the Schneider model. 2.In Mech_comp_properties keyword the required inputs for the Schneider model are defined. Note that in the spreadsheets and in the main text and tables in the present tutorial we present the compressibilities in 1/km units but the data must be input according to the length units used in the simulation (generally 1/m). 3.In Mech_comp_settings the values for pc/p' and k0 are defined. Note that the values shown on the left are those found after running the k0 single element test to refine the initial guess. 4.In this example optional keywords defining hardening-related parameters are input for reference. Note that the input values in the present example are the default values. Those optional keywords comprise: a.Mech_comp_min_porosity defining the residual (minimum) porosity b.Mech_comp_max_depth defining the maximum depth used to evaluate and derive the hardening law c.Mech_comp_num_points defining the number of points used to define the final hardening data used in the simulation. Note that internally 10000 points are used to evaluate the hardening function in order to account for the non-linear elasticity and strains, from which 35 in this case are extracted for its usage. |

Case01b

The mechanical compaction data in Mat_001d_Case01b.mat is discussed below. This case demonstrates the minimal input required.

Data File |

|

* Material_data ! ------------------------------------------- Name "Mech_20_00_80_00" ! ---------------------------------------------- Mech_comp_type 2 ! Athy Mech_comp_properties IDM=2 /Porosity dep/ 0.642 /Compressib./ 0.000726 ! 1/m Mech_comp_settings IDM=2 /pc to p' rat./ 1.05 /k0/ 0.81

|

1.Mech_comp_model is set to 2 to use the Athy model. 2.In Mech_comp_properties keyword the required inputs for the Athy model are defined. This example use equivalent properties to those in Case01a. 3.In Mech_comp_settings the values for pc/p' and k0 are defined. 4.In this case no optional keywords are defined.

|

Results

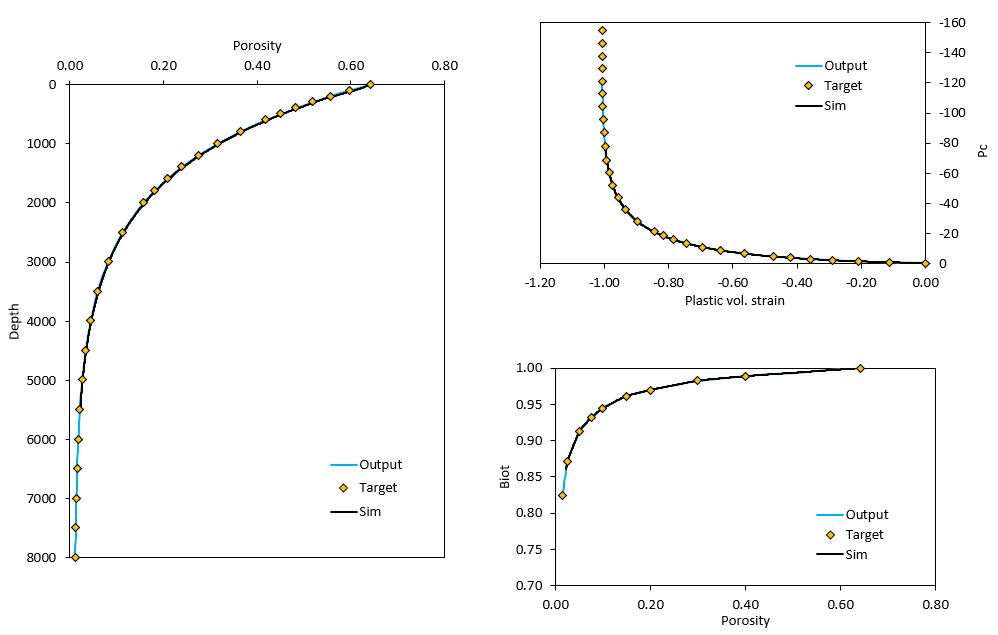

The results are provided in Mat_001d/Case01/Results. The spreadsheets 00_Mat_001d_Case01a.xlsx and 00_Mat_001d_Case01b.xlsx contain the simulated end results extracted via a Plot Over Line in ParaView, validated against the target values. The figures below are provided within the "Compaction_Output_Check" sheet. In those figures "Target" reefers to the values calculated in the spreadsheet, "Output" refers to the values output at the start of the simulation by ParaGeo in a .hdh file within the Compaction sub-folder and "Sim" refers to the simulated results.

Validated results in the spreadsheet (compaction curve, hardening) as well as the used Biot function of porosity. Target refers to the values calculated in the spreadsheet, Output refers to the values output in the .hdh file by ParaGeo and Sim refers to the simulated results.

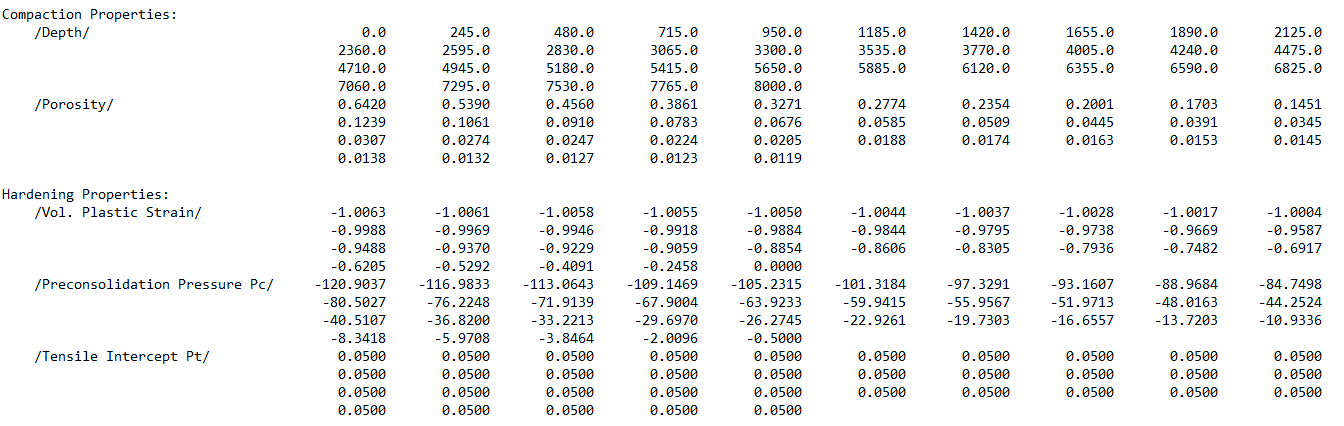

Note that in the .res file the user may search for "Compaction Properties:" in order to obtain data with a format ready for copy paste in terms of:

1.Porosity vs. depth that may be used in geostatic via Spatial_variation_values . 2.Hardening properties in a table format, in case the user is interested in defining a material file with the values in tabular format (not generally needed / recommended).

Data output in the .res file

|