Case03b HM Coupled (Low Perm Fault)

The present case is a variation of the HM coupled depletion example with low perm contact fluid flow at the fault. All data files are identical to Case03a with the exception of Contact_property data for "Fault_sand" where the intrinsic permeabilities for the fracture and filter cake (fault gouge) are defined 1·103 and 1·106 lower, respectively, at 1.157·10-17 m2 (same intrinsic permeability as that for "Fault_shale"). Note that the simulation run completes in 1.6 hrs on a 3.6 GHz AMD processor machine.

The data files for the project are in: MEM_001\Case03\Data and the only files different from Case03a are:

•MEM_001_Case03b.dat

•MEM_001_Case03b.contact

The following example must be undertaken beforehand:

1MEM_001 Case03 HM Coupled (High Perm Fault).

Data File (.contact) |

|

* Contact_property NUM=1 ! ---------------------------------------- Name "Fault_sand" (...) Flow_model_normal 11 Flow_properties_normal IDM=2 /Intrinsic Permeability (Fracture)/ 1.157E-17 /Intrinsic Permeability (Filter Cake)/ 1.157E-17 Flow_model_tangential 11 Flow_properties_tangential IDM=1 /Intrinsic Permeability/ 1.157E-17

|

1.In MEM_001_Case03b.contact, intrinsic permeabilities for the fracture and filter cake (fault gouge) are defined in Contact_property for "Fault_sand" to be same as that in "Fault_shale", i.e. 1.157·10-17 m2.

2.Note that the "Fault_sand" contact property is used by Fault_set "Fault01".

|

Data File (.dat) |

|

! --------------------------------- * Include ! --------------------------------- Filename MEM_001_Case03b.contact

|

1.Include MEM_001_Case03b.contact in MEM_001_Case03b.dat data file.

|

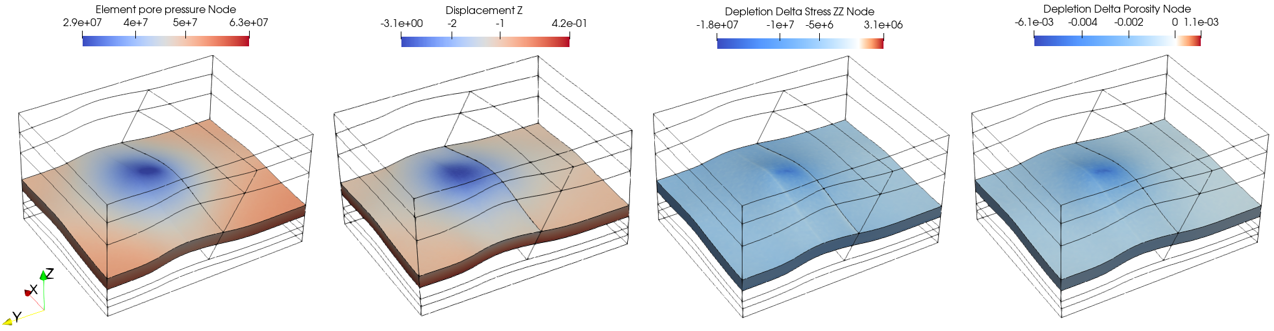

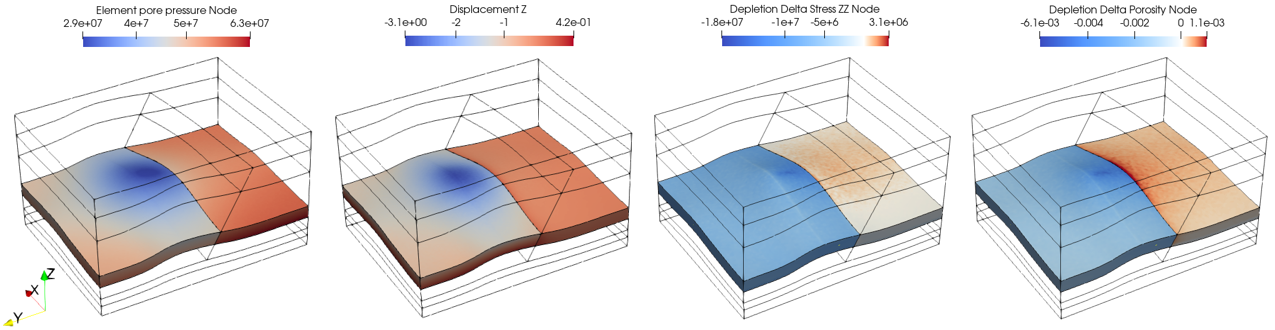

Results

The figures below show a comparison of results with contact flow (Case03a) and without contact flow (Case03b) for pore pressure, vertical displacement, change in vertical stress and porosity in the reservoir. Observed is a distinct contrast of results across the fault line for the case with low perm contact flow which highlights the influence of depletion in the reservoir. The drawdown at producer well 3 which has significantly depleted the pore pressure in the reservoir on the hanging wall fault side has increased compaction leading to an increase in vertical effective stress and consequent reduction in porosity, but due to the fault being relatively impervious (low perm contact flow), the reservoir pore pressure on the footwall side has been largely unaffected and shows minimal change in vertical displacements, vertical stress change and porosity change. Note that the contour key ranges for the two cases have been set consistent for all the variables in order for a like-for-like comparison.

(a) Case03a: High perm contact flow

(b) Case03b: Low perm contact flow

Comparison of reservoir results for (a) Case03a (with high perm contact flow) vs (b) Case03b (with low perm contact flow) for pore pressure, vertical displacement, change in vertical stress and porosity.

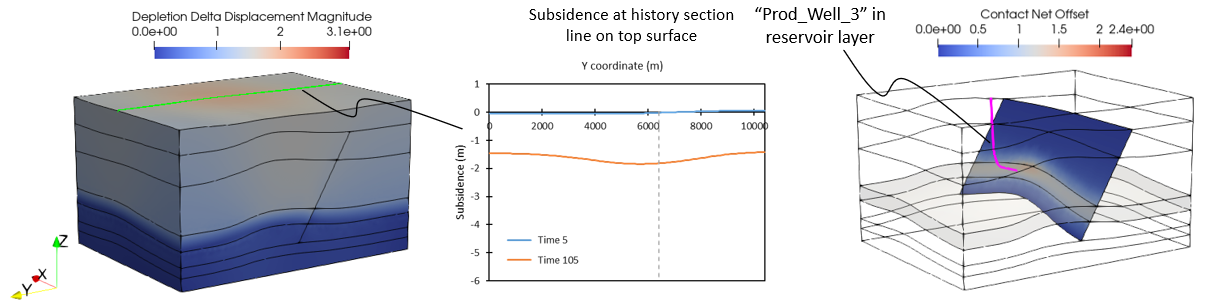

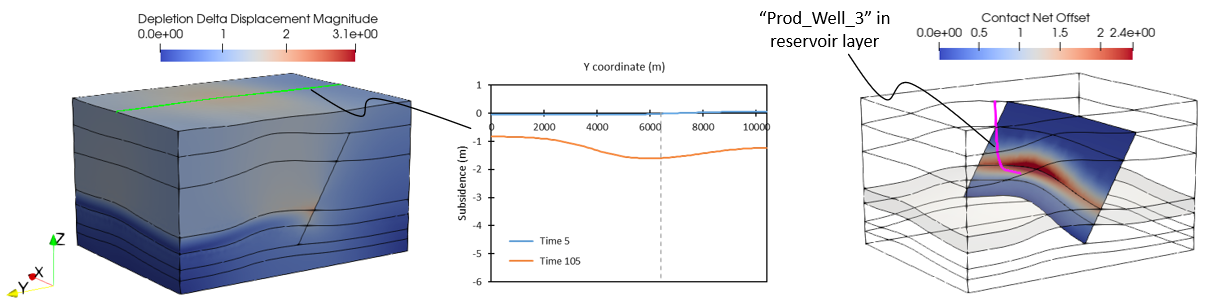

The figures below show a comparison of results with high perm contact flow (Case03a) and with low perm contact flow (Case03b) for subsidence on the top surface and the non-linear contact slip. Observed with the low perm contact flow case is an increase in contact plastic slip (shown as contact net offset) at the fault and a marginal increase in top surface subsidence on the footwall side where the producer well 3 is located. Most of the slip occurs near the producer well 3 location at the top of the reservoir.

(a) Case03a: High perm contact flow

(b) Case03b: Low perm contact flow

Comparison of results for (a) Case03a (with high perm contact flow) vs (b) Case03b (with low perm contact flow) for change in displacement, top surface subsidence at the history section line "SubsidenceY" (green line) and contact plastic slip (net offset).