Case02 With Contact Advection along Fault

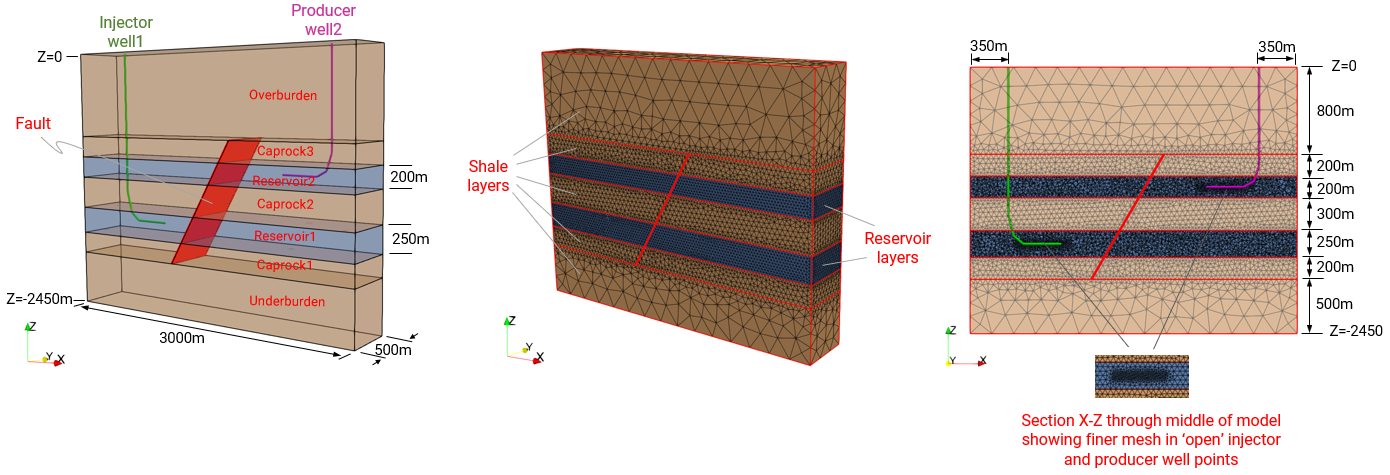

The primary goal of this example is to demonstrate contact advection along the fault. The cold injection fluid is drawn from the lower reservoir1 up and along the fault to the upper reservoir2. The example also include definition of well history data.

The files for the project are in directory: ParaGeo Examples\General Examples\Ex_008\Case02. Only the key data associated with usage of well elements, contact property and transient time step growth solution data will be described here. A tutorial on how to generate the geometry for the Case01 example using Gmsh is available in Gmsh_002, albeit with slightly different mesh refinement. The geometry and mesh for Case02 are similarly created.

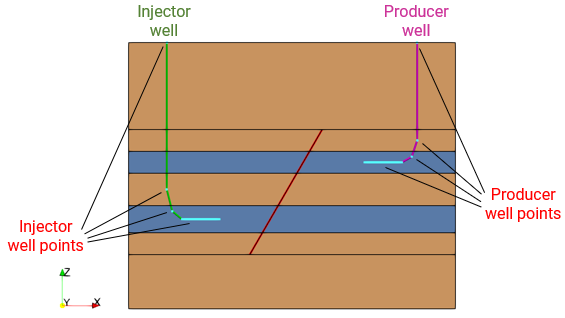

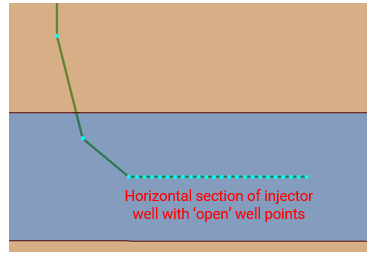

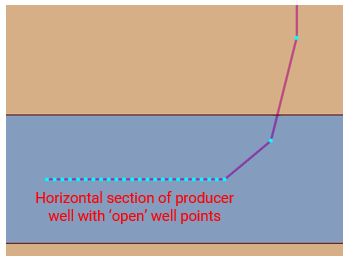

Note that the injection and production wells are not 'active' until stage 4 and 5 respectively, however, it is recommended that the wells are defined in stage 1 with the well points 'shut' and then updated to 'open' when they come online in the later stages. This enables the user to visualize and track the wells throughout the simulation.

|

Model and Mesh Definition |

Key contact property data with advection (.contact)

•Contact advection data is highlighted in bold on the lhs panel below. In this example, the advection conductivity values are defined the same as the layer material grain thermal conductivities. •A one metre damage zone is defined for the fault Contact_width.

|

Key data for well definition in Stage 1 with well history

Well_definition #1 (Injection well)

Well_definition #2 (Production well) •Notice that Well_temperature is not defined for the production well as it only makes sense to define this data for the injected well fluid.

|

| Key data for well definition in Stage 4 injection and Stage 5 production |

Once the wells come online, the well data previously defined in stage 1 still applies and the re-definition well data need only consist of the name of the well, the status distribution (and well loading time curve if different from previously defined).

Well_definition #1 (Injection well)

Well_definition #2 (Production well)

|

| Key data for solution control in Stage 6 injection and production flow over pseudo-84 years duration |

To demonstrate contact advection up and along the fault to the produced upper reservoir layer, a pseudo long duration of 84 years is simulated. It is not uncommon in reservoir injection and production simulations which take place over a long duration (typically 15 to 30 years) that steady-state flow occurs where the pore pressure in the injected/depleted reservoir remains constant. Under these conditions, the model simulation does not require small time steps to capture the change in pore pressure as there is little/no pore pressure change, hence the simulation can be performed using large time step increments. To achieve this, a transient time step growth factor in the solution control data can be defined.

|

| Results |

The result files for the project are in directory: ParaGeo Examples\General Examples\Ex_008\Case02\Results.

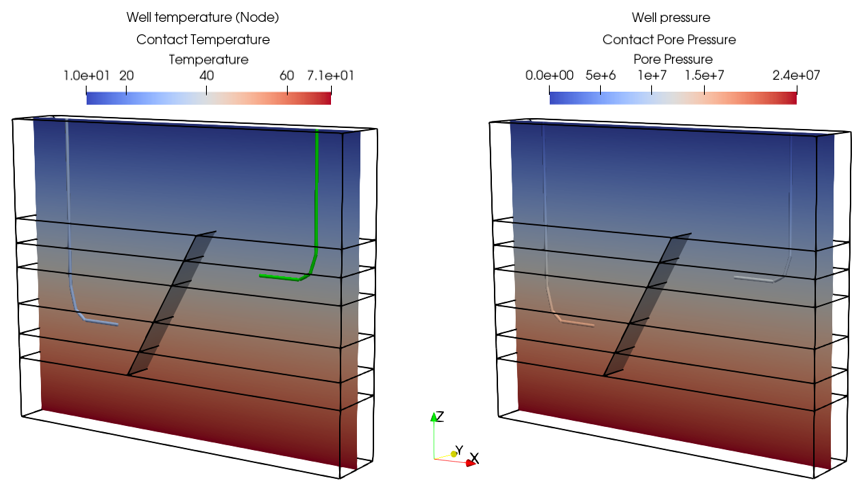

The results below show the initial condition of the model with depth-dependent spatial temperature gradient from 10°C at the surface to 71°C at the base of the model and hydrostatic pore pressure for the whole model. Injected well temperature is at 30°C.

Initial Condition: Depth-dependent spatial temperature gradient and hydrostatic pore pressure

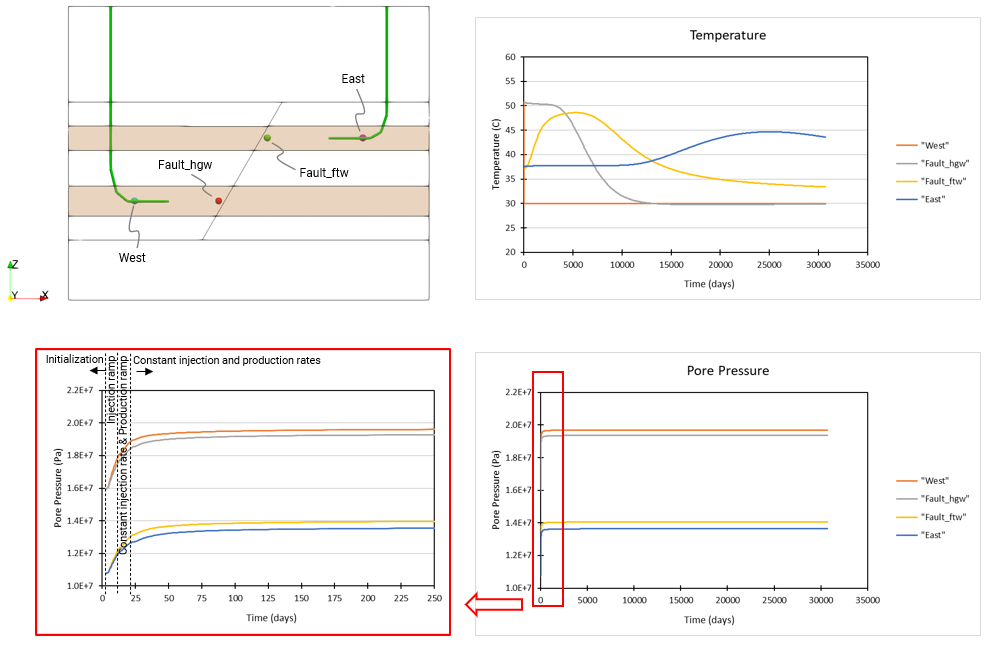

Below shows the plots of temperature and pore pressure distribution throughout the simulation time at four history points located in the injected and depleted reservoir layers. Notice that the pore pressure is near constant after 230 days with maximum over-pressure of c.a. 3.7MPa in the vicinity of the injected 'open' well point 'west'. The heat transfer of the well injected temperature of 30°C from 'west' to 'east' progresses slowly through time with the fault hanging wall (grey curve) only 'seeing' the injected fluid temperature after 10,000 days (c.a. 27years). The fault footwall (gold curve) in the produced upper reservoir layer initially 'sees' an increase in fluid temperature from the higher temperature lower reservoir transported through advection. This is followed subsequently with a decrease in fluid temperature when the colder injection fluid reaches this history monitoring point.

History points in injected/depleted reservoir layer and the temperature and pore pressure distribution at these points over simulated model time

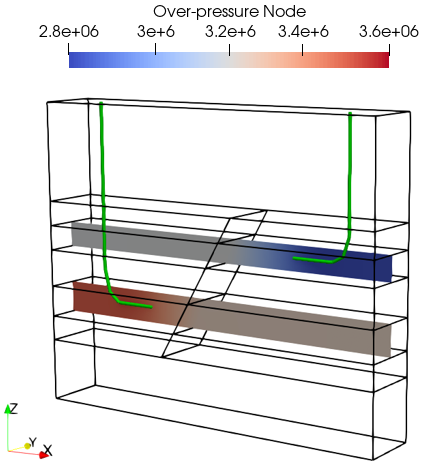

Constant over-pressure in both reservoir layers is observed in the plot below 230 days of injection and depletion with maximum over-pressure of c.a. 3.6MPa in the injected lower reservoir and c.a. 2.8MPa in the produced upper reservoir.

Over-pressure in the two reservoir layers

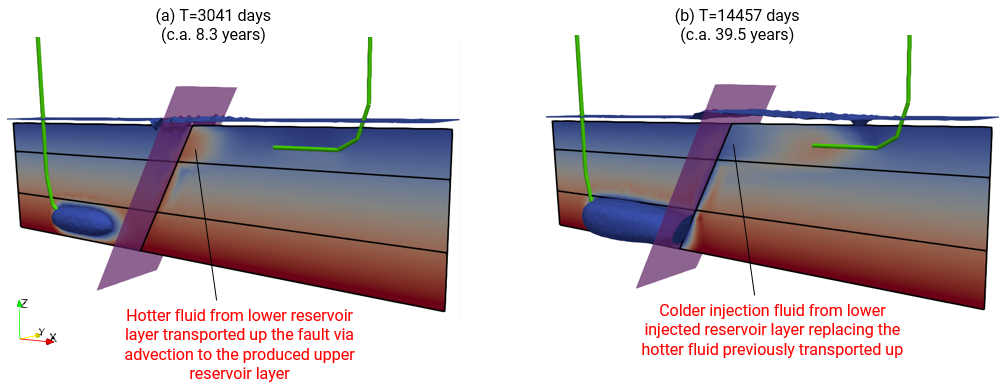

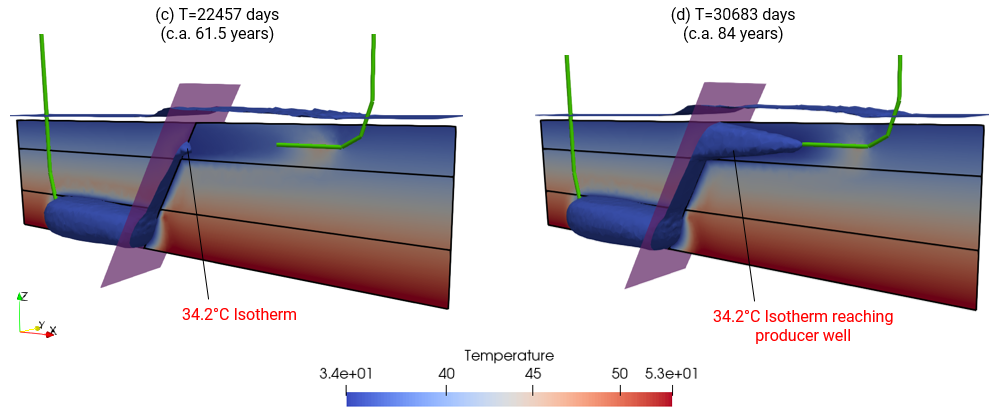

The evolution of the 34.2°C isotherm and temperature distribution from advection (including along the fault) is shown in the plots below in the two reservoir layers with caprock sandwiched in between. Plot (a) shows the hotter fluid from the lower reservoir layer transported up and along the fault to the upper reservoir layer via advection. In plot (b), this fluid is subsequently replaced by the colder injection fluid along the same flow path up the fault. Plot (c) shows the progression of the 34.2°C isotherm into the upper reservoir layer and reaching the producer well in plot (d).

Evolution of 34.2°C isotherm and temperature distribution showing advection flow along the fault from lower reservoir injector well to upper reservoir producer well

|