Case01 Base Case

Following is the description of the data file for the project which is located in Imp_001/Case01/Data. Note that the data is not described in the same order as it appears in the data file but in an order that facilitates understanding of the model set up instead (i.e. geometry first, then mesh, then groups, etc.).

Also note that usage of the implicit solver for the geomechanical field is defined in Control_data exclusively whereas the rest of the data is common to an explicit case. Thus the present data file description is divided in two sections; first one defining the problem definition data and the second one defining Control_data set up for the implicit solver.

Geometry The geometry of the model is defined towards the end of the data file after the END DATA command.

Geometry sets

Mesh

Group data

Material data

Support data

Loading data

Loading data corresponding to the internal pressure is defined.

History output

|

Control data for the implicit solver

Usage of the implicit solver and the parameters defining the time increment, convergence criteria, etc is defined exclusively in Control_data.

|

Results

The results for the project are located in Imp_001\Case01\Results.

Case01

The summary of step and convergence data printed both at the command prompt and the .res file is shown in the following table. In red is shown the data of the steps that did not converge. As can be seen at step number 3 the time increment increased above the initial one because in the previous two steps less iterations than the target were required (which means that the code is converging easily and thus larger time increments may be used). It can be noted that from step 5 onwards more than 2 iterations are required to converge as plastic strains start to develop from those steps.

Summary of step and convergence results for Case01

Case01a

Case01a is set with the objective to obtain a solution for internal pressures of 0.1 GPa and 0.18 GPa respectively for which an analytical solution is provided in de Souza-Neto et al. (2008). Provided that the maximum internal pressure has been set to 0.2 GPa and the Time_curve_data has been set so that it is applied following a linear function from t=0 to t=1, the times corresponding to internal pressures of 0.1 GPa and 0.18 GPa are t=0.5 and t=0.9. Thus the Control_data for Case01a is set so that a constant time increment is used for the implicit solver as shown below.

The resulting time step and convergence data is summarized in the table below. The steps that did not converge are shown in red. The steps for which solution is compared to the analytical solution in de Souza-Neto et al. (2008) is shown in green. As can be seen, because Target_number_iterations was not set the time increment is kept at 0.05 even though the first 10 steps have converged with just two iterations. Note that from step 11 onwards more than 2 iterations are required as it is when plastic strains start to develop.

Summary of step and convergence results for Case01a

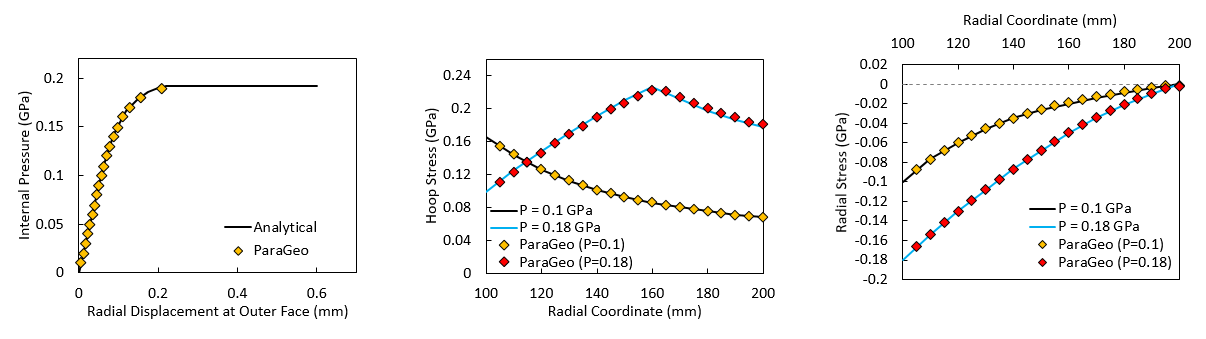

In the plots below the solution obtained from ParaGeo is compared to the analytical solution provided in de Souza-Neto et al. (2008).

The first plot on the left shows the radial displacement in the outer surface of the cylinder as a function of the applied internal pressure. As can be seen ParaGeo solution is in good agreement with the analytical one which shows an initial linear elastic behaviour for internal pressures of 0 to c.a. 0.1 GPa and starts to behave in a non-linear manner for larger pressures. It can be seen that the analytical function shows a maximum internal pressure that can be achieved which can no be exceeded. This corresponds to the collapse pressure that occurs when the plastic front reaches the outer surface (the entire cylinder becomes plastified) with continuously increasing displacements at constant pressure. De Souza-Neto et al. (2008) estimated that collapse pressure corresponds to 0.19209 GPa for the current problem. As can be seen with the current set up an approximation of such collapse pressure has been obtained at step 19 (pressure of 0.19 GPa) with the subsequent steps not converging (as the solution is not unique for pressures larger than the collapse pressure).

The two plots on the center and on the right show the hoop and radial stress distribution along the cylinder radius for applied internal pressures of 0.1 GPa and 0.18 GPa respectively. As can be seen ParaGeo solutions are also in good agreement with the analytical solutions. As can be seen for an internal pressure of 0.1 GPa the maximum hoop stress is located at the internal face, because plastic strains have still not developed. For larger pressures plastic strains develop starting at the inner surface and the plastic front moves towards the outer surface as internal pressure increases (see that the maximum hoop stress for an internal pressure of 0.18 is at a radial coordinate of c.a. 160 mm). Note that the maximum hoop stress is located next to the plastic strain front. The radial stress is maximum at the internal surface where it is equal to the internal pressure and decreases to zero towards the outer surface.

Comparison of analytical solution provided by de Souza Neto et al. (2008) and ParaGeo results for stresses and displacements.

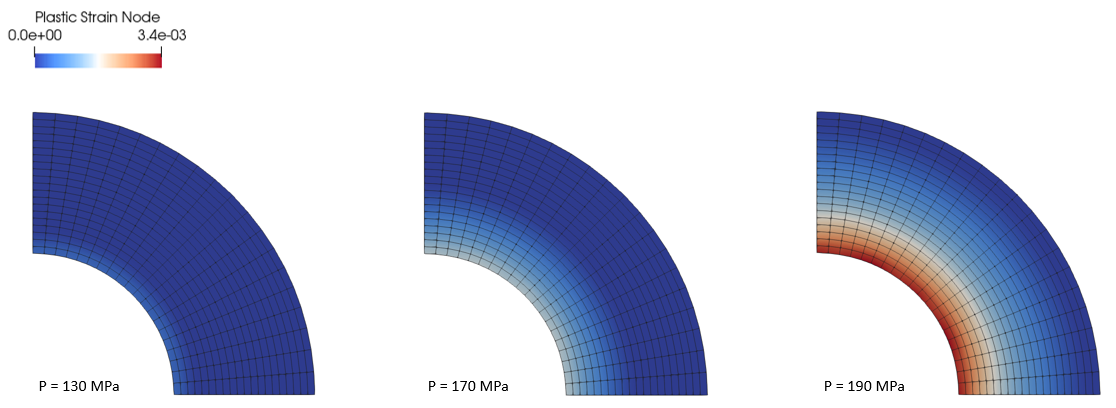

In the plots below plastic strain distribution for three internal pressures is shown. As can be seen the plastic strain front moves from the internal surface at early times to the outer surface as internal pressure increases.

Evolution of plastic strain distribution as internal pressure increases.

Case01b

An additional case Case01b is set to demonstrate the effect of the implicit solver-related keywords setup on the convergence results and steps performed. The data set up is shown below.

The summary of results for steps and convergence is shown below. For the present case the simulation is terminated after step 8 because the time increment attempts to decrease below the minimum allowed value set via Minimum_time_increment.

Summary of step and convergence results for Case01b

|

References

Eduardo A. de Souza Neto, Djordje Peric and David R. J. Owen. Computational methods for plasticity: Theory and aplications. (Wiley, Chichester, 2008), pp. 244-247

|