Case02 Usage of geometry sets

The data file for the project is: Intro_001\Case02\Data\Intro_001_Case02.dat. It is assumed that the user has undertaken Case01 first. Most of the data in the data file is identical to such case and hence full description of the datafile is not provided here. In the present case the focus is made on:

1.Definition of several ParaGeo groups

2.Definition of geometry sets and its usage for application of boundary conditions

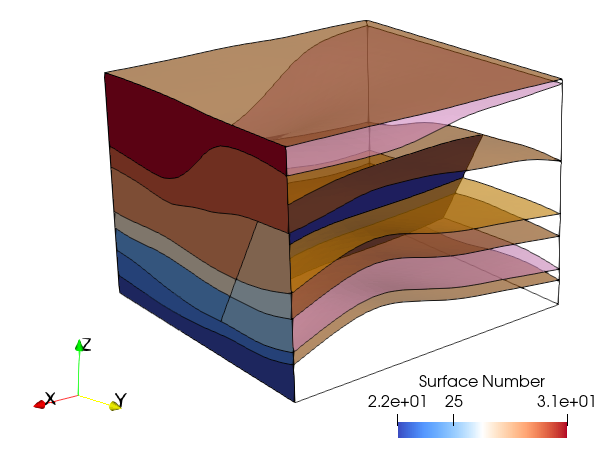

The model geometry is defined as shown in the figure below. The domain is defined via 4 surfaces (S1, S2, S3 and S4). Those surfaces will be used to define 3 ParaGeo groups (Sand, Sand2 and Sand3) each one defined by a single element. Geometry sets will be defined for all model boundaries and will later be used to facilitate definition of the boundary conditions. Boundary conditions will consist of rollers at the base and West boundary, a stress load that will be applied from time t=0.0 to t=1.0 and then held constant until t=2.0 and a displacement boundary condition applied on the East boundary from t=1.1 to t=2.0.

Model geometry and groups (left), geometry sets (middle) and boundary conditions (right)

Definition of multiple ParaGeo groups

The present case considers 3 ParaGeo groups. The set up of the Group_data and Group_control_data is shown below.

Group_data

Group_control_data

|

Definition of geometry sets

Geometry sets allow to define sets of geometry entities that later can be used to define boundary conditions, assign properties, etc. Geometry sets may contain several points, lines, surfaces and volumes (including combinations of those). Below the definition of geometry sets for the four model boundaries are shown.

It should be noted that a given geometry entity may be included in more than one geometry set (e.g. lines 2 and 3 may be included also in an additional geometry set that we will call "East_bottom" in addition to the already defined "East").

|

Usage of geometry sets in defining boundary conditions

The defined geometry sets may be used to assign boundary conditions for example. This is illustrated here:

Support_data

Loading data

|

Results

The results for the simulation are in Intro_001\Case02\Results.

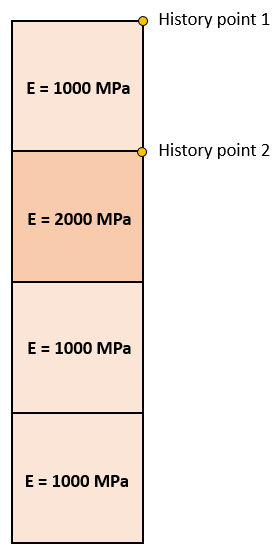

In the file Intro_001_Case02_001.hdh there are the results for the History_point set data number 1 which in this case is set to output results at two point locations. Point 1 is located at the top right corner of group 3 (surface number 4) whereas Point 2 is located at the top right corner of group 2 (surface number 3). Note that point 2 is located in the group that has assigned material properties named "Elastic2" which has a Young modulus of 2000 MPa instead of 1000 MPa (see the picture below). Also note that in the file the columns show the results following an order such as: Disp_x (point 1), Disp_x (point 2), Disp_y (point 1), Disp_y (point 2), etc.

Young modulus of each element and location of the two history points

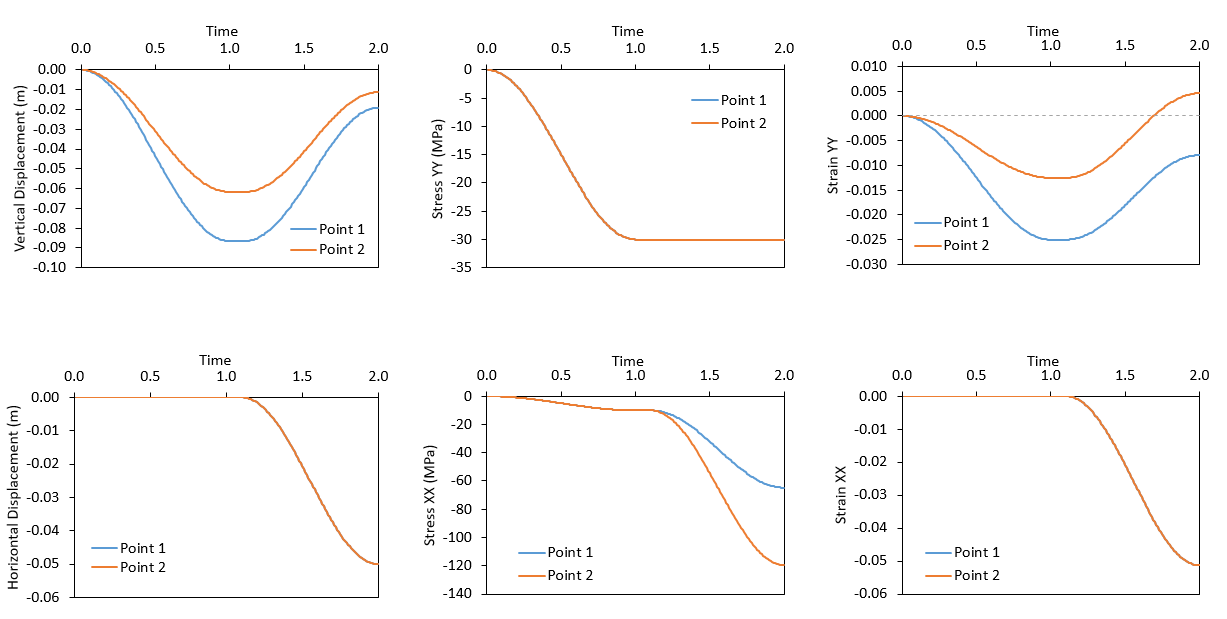

Below the history results for vertical and horizontal displacements, stresses and strains are plotted for the two points. It can be seen that:

1.Stress YY evolution for the two points is consistent with the load prescribed by Global_loads and Time_curve_data number 1 in which a stress of 30 MPa is applied at the top surface and is ramped up from t=0 to t=1 following an S-shape curve and then kept constant. The S-curve function used to ramp up the stress is evident in the plot.

2.Horizontal displacement for the two points is consistent with the load prescribed by Global_loads and Time_curve_data number 2 in which a leftward (negative) displacement is applied to the "East" boundary and ramped up from t=1.1 to t=2 following an S-shape function. Again the S-shape curve is evident in the plot. It can also be noted that horizontal strain is consistent with horizontal displacement.

3.At t=1.0 (end of the top stress load application) the vertical strain (Strain YY) for point 1 is twice as much as the vertical strain for point 2 (-0.25 and -0.125 respectively), because Young's modulus for point 1 was half of the Young's modulus of point 2. From t=1.1 to t=2.0 vertical strain for the two points increased the same amount as a result of the Poisson ratio effect from the horizontal strain (both materials have the same Poisson's ratio).

4.Stress XX from t=0 to t=1 increases because of the applied vertical stress and the roller constraints on side boundaries. From t=1.1 to t=2 the increment in stress for point 2 is twice as much as the increment for point 1 because of the Young's modulus.

Evolution of vertical and horizontal displacements, stresses and strains for the two points

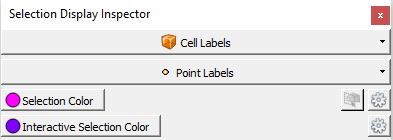

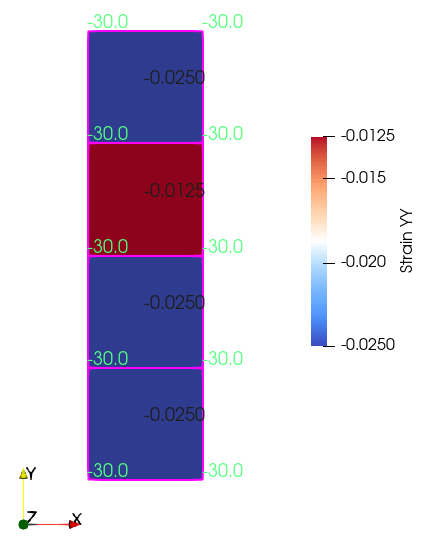

We can load the file Intro_001_Case02.xmf in ParaView to visualize any output plot file we wish. Lets select time 1.0 and lets plot Strain YY. Also we are going to activate the selection display inspector, which allow us to see the values of any variable we select for the selected elements. To do that we should go to the menu View/Selection Display Inspector. Its window will be displayed on the right of the screen as shown:

Selection Display Inspector window

In Cell Labels and Point Labels we can select the variables to be inspected when an element / node is selected respectively. We will click on Cell Labels and select Strain YY. Also we will click on Point Labels and select Stress YY. Then we are going to use the selection tools in ParaView to select all the elements. You can find them in small icons just above the main display window as shown here:

View and Selection Tools Icons in ParaView

We are going to click on the

Inspected vertical strain and stresses at elements and nodes respectively

|

Concluding Remarks

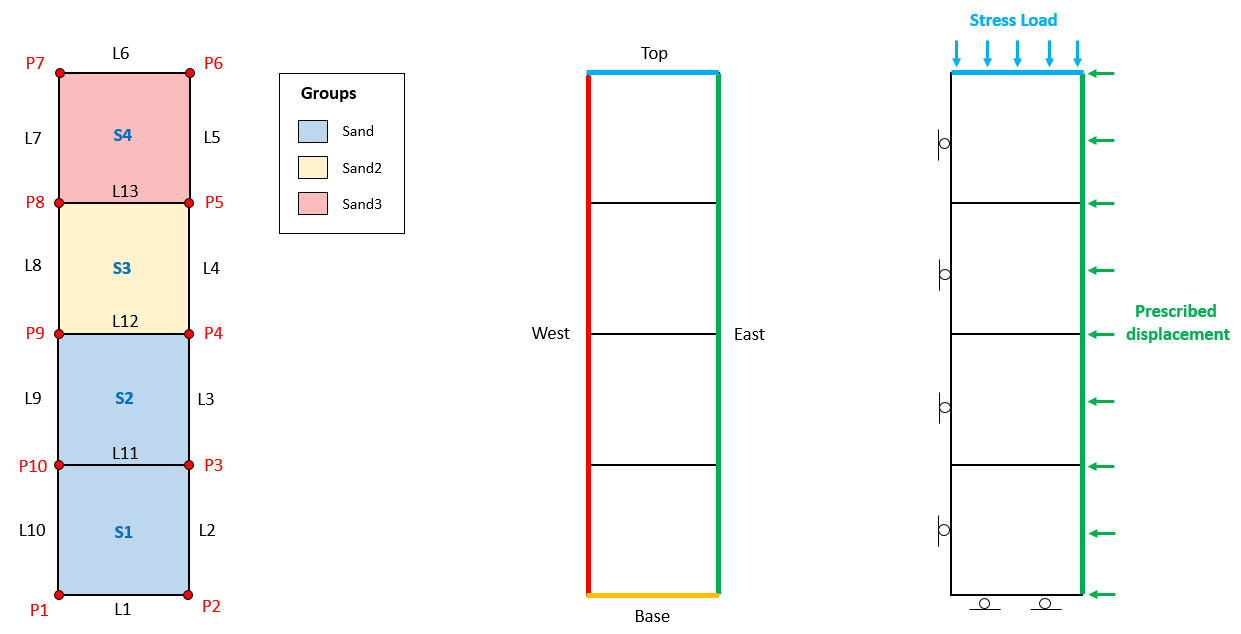

It has been shown that geometry sets are a convenient way of grouping geometry entities to be used later to assign boundary conditions. They can be also used to define groups, define stratigraphy, etc. The present example has considered a very simple geometry for demonstrative purposes but in more complex geometries which may involve multiple surfaces at boundaries, geometry sets become essential in simplifying model data definition (see for example the figure below).

Surfaces included in the "East" geometry set for a relatively complex geometry involving 7 stratigraphy units (top horizons shown here) and a fault.

|