ParaGeo groups are geometric regions with specific properties, material assignments, individual stratigraphy layers, etc. ParaGeo groups may encompass one or several surfaces in 2D problems and one or several volumes in 3D problems. Two compulsory data structures are used for the definition of ParaGeo groups; Group_data and Group_control_data

Group_data

The Group_data data structure is compulsory and defines the properties for each geometry group. For this example these comprise:

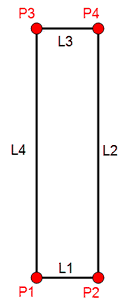

1The name of the group. 2The element type. 3The material properties to be assigned to the group. 4The porous flow type which may be: (a) 0 - Non-porous materials - bulk density defined by the value specified in the grain density (b) 1 - Dry porous material - bulk density defined using grain density and porosity (c) 2 - drained analysis with non-zero pore pressures (both grain density and fluid density must be specified) (d) 3 - Undrained analysis (both grain density and fluid density must be specified) (e) 4 - Coupled geomechanical/porous flow (both grain density and fluid density must be specified) (f) 5 - Drained effective stress analysis (pore pressure not defined) - bouyant bulk density 5 The surface that defines the geometry for the group.

|

|

* Group_data NUM=1

Group_name "Sandstone"

Element_type TPM3V

Material_name "Sandstone"

Porous_flow_type 1

Surfaces IDM=1

1

|

1Group 1 is named "Sandstone" and is defined using the TPM3V (Triangle Plane Membrane with 3 nodes using the average Volume formulation). 2The group is assigned material named "Sandstone". 3The porous flow type is 1; i.e. dry material. 4The geometry is defined by surface 1. |

Group_control_data

The Group_control_data data structure is compulsory and defines:

1The number of geometry groups in the problem, where each geometry group relates to a region with specific properties; e.g. regions with different material assignments, individual stratigraphy layers, etc. 2The group number. 3Whether the group is active or inactive in the fields; i.e. geomechanical, porous flow, thermal, that are being solved.

Data File

|

|

* Group_control_data

Group_numbers IDM=1

1

Active_geomechanical_groups IDM=1

1

|

The problem has a single group (Group 1) that is active in the geomechanical field.

|

|