Case01 and Case02 Comparison of node-to-node and node-to-facet contact algorithms

Basic Set Up: Data File Description

The initial data file for the project is: Cont_003\Data\Cont_003_Case01.dat. The basic data includes:

1Geometry_data to read the .geo file containing the geometry and mesh. 2Geometry_set data for all model boundaries, fault and detachment surfaces and stratigraphic horizons. 3Contact data (Contact_set, Contact_property, Contact_surface and Contact_global). 4Group data for the four formations (Group_control_data and Group_data). 5Material_data and Fluid_properties defining the elastoplastic properties for all formations. 6Support_data to define displacement constrains to the boundaries. 7Gravity_data for gravity initialisation during the first stage. 8Geostatic_data assigning the initial porosity distribution and Geostatic_control_data appropriate for each initialisation stage defined within the geostatic.set file. 9Load data and the associated time curve defining a tectonic compressive displacement of 80 m applied during the second stage to the East_top boundary (Global_loads, Time_curve_data and Load_case_control_data). 10Damping_global_data defining a velocity damping (Percentage_damping) of 0.02 11Control data (Control_data) for four stages defining: (a) Factor of critical time step = 0.5, (b) Incremental solution algorithm (Type 1), (c) Maximum number of time steps of 106 (very large) (d) Target_number_time_steps of 10000 per stage (e) Stage duration of 0.25 Ma each, (f) Plot file output at the end of each stage, (g) Plot file output every 0.05 Ma, (h) Screen message output every 500 mech steps.

|

Contact Data

Here the contact data for the present example is discussed. Note that data for cases Case01 and Case02 is almost identical except that in Case01 the node-to-node algorithm is adopted as opposed to Case02 in which node-to-facet algorithm is used. This is defined using the keyword algorithm within the Contact_global data structure. The contact data encompasses Contact_global, Contact_set, Contact_property and Contact_surface data structures.

Contact Global data

Contact Set data

In this case a single Contact_set data is defined which encompasses all the contact surfaces. It is noted that for node-to-node algorithm contact interactions should be limited so that each contact surface can only interact with another contact surface (no more than one). This may be achieved by defining different Contact_set data for each pair of contact surfaces or by defining Contact_surface data structures which establishes the allowed interactions. In the present case the later method is used.

Contact Surface data

Contact Property data

|

Results

The result files for the project are in directory: Cont_003\Results. Note that for the sake of disc usage only results at the end of each stage are provided.

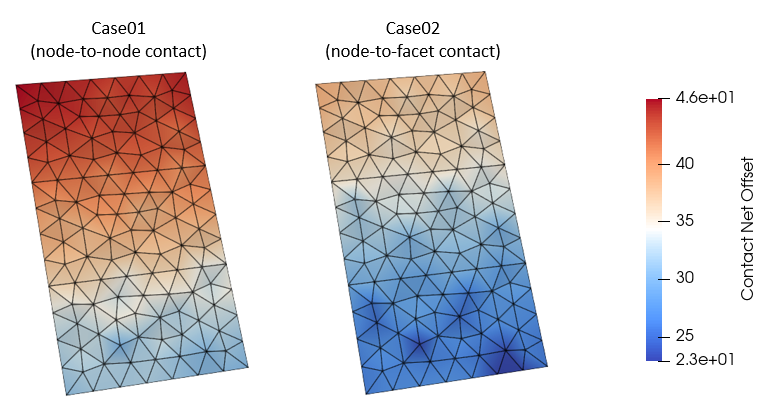

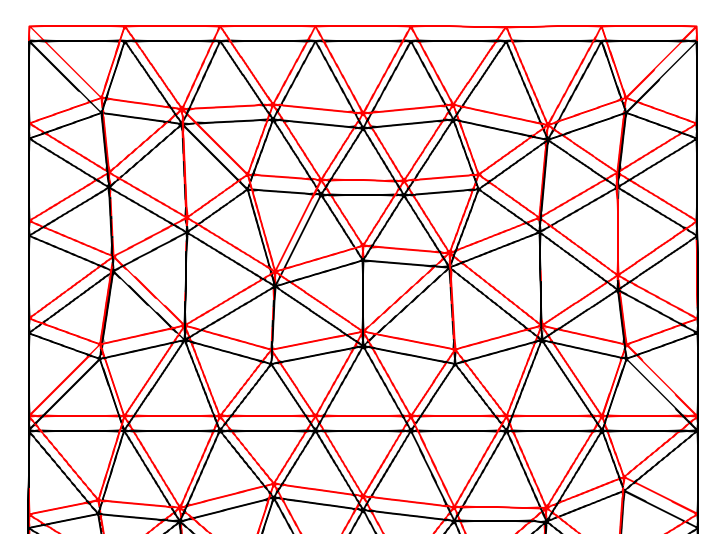

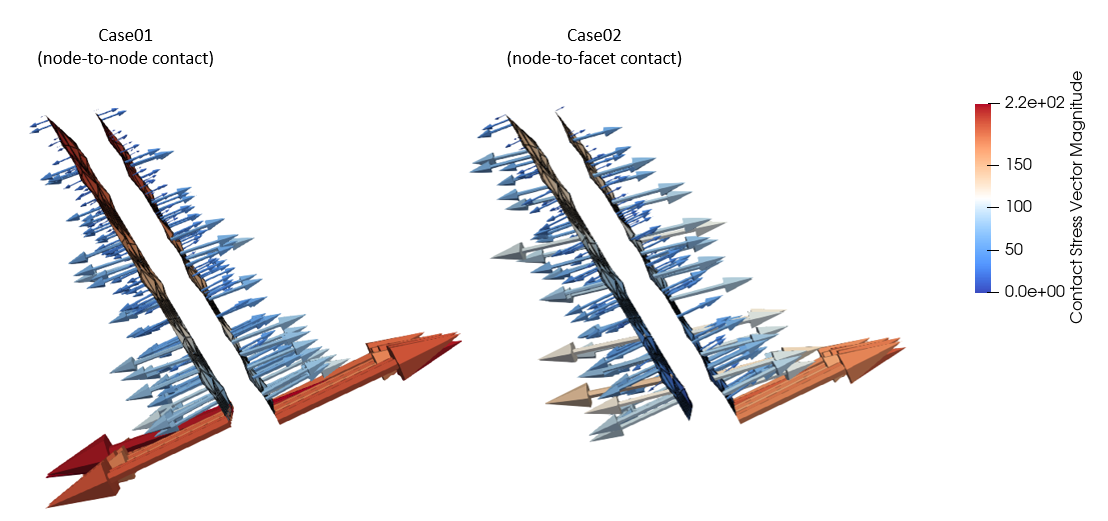

Below are some pictures showing the results at the end of the contact release stage. The end of such stage is chosen to discuss the results because a displacement reinitialisation is performed during the fourth stage and consequently the contact behaviour is less obvious at the end of the simulation. From the results it can be seen that:

1.The node to node contact resulted in a larger contact offset.

2.The node to node contact resulted in a more homogeneous contact stress direction and magnitude distribution.

Both observations are a consequence of the fact that:

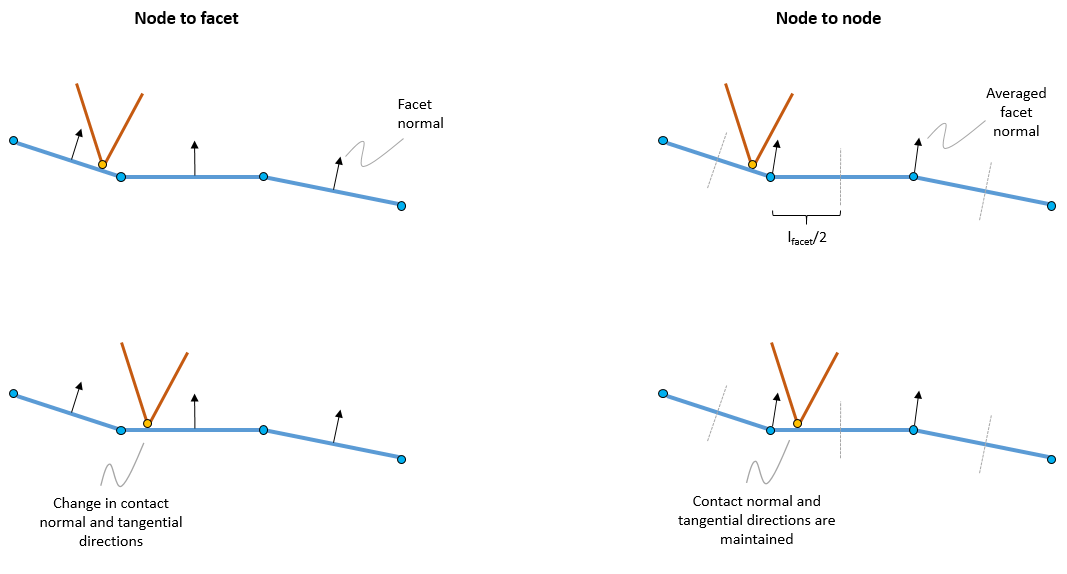

1.The node to node contact algorithm considers more homogeneous and smooth contact normal direction as for each node it uses the average of the connected facets normals.

2.For the amount of displacement there is no change in contact directions for any of the nodes in Case01 as the normal direction zone for each node extends to half of the connected facet length.

This is illustrated in the last figure.

Comparison of contact net offset for Case01 and Case02 at the end of the contact release stage.

View of the fault mesh at the end of the contact release stage. Fault hanging wall (red) and fault foot wall (black).

Comparison of contact stress vectors for Case01 and Case02 at the end of the contact release stage.

Schematic of update in contact directions for node-to-facet (left) and node-to-node (right) algorithms

|