Materials

INDEX

Title |

Analysis Type - Features List / Utility |

Model |

Material Models |

||

Mechanical (2D) |

|

|

•SR4 material model |

|

|

•Case 1 Simulation of Triaxial Tests with the SR4 model •Case 2 Characterization of Experimental Data with the SR4 Model (Linear Elasticity) •Case 3 Characterization of Experimental Data with the SR4 Model (Poroelasticity) |

•Triaxial tests •Material characterization of experimental data for SR4 model with linear elasticity/poroelasticity |

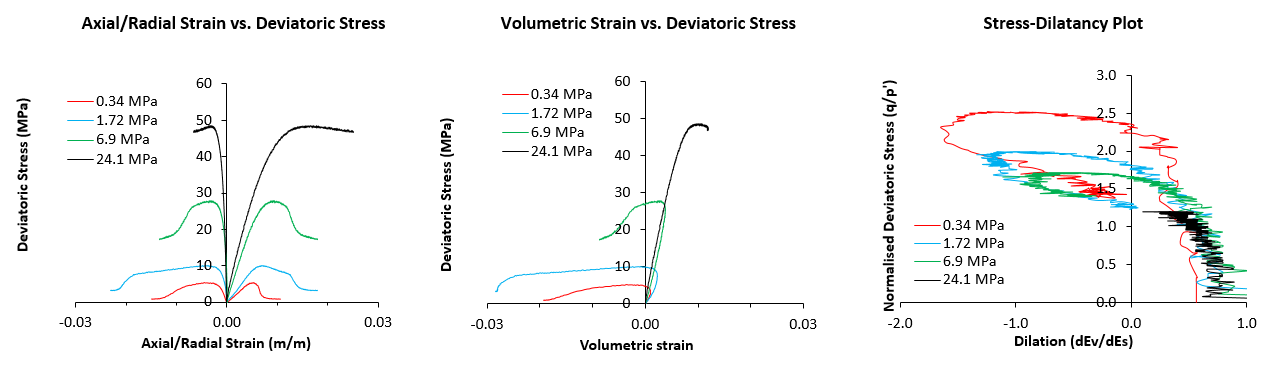

Plots from experimental tests |

Mechanical (2D) |

|

|

•SR4 material hardening parameters and calibration of kappa and lambda using SR4 analytical model |

|

|

Mechanical (2D) and Coupled THM (2D) |

|

|

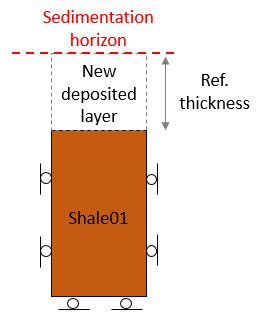

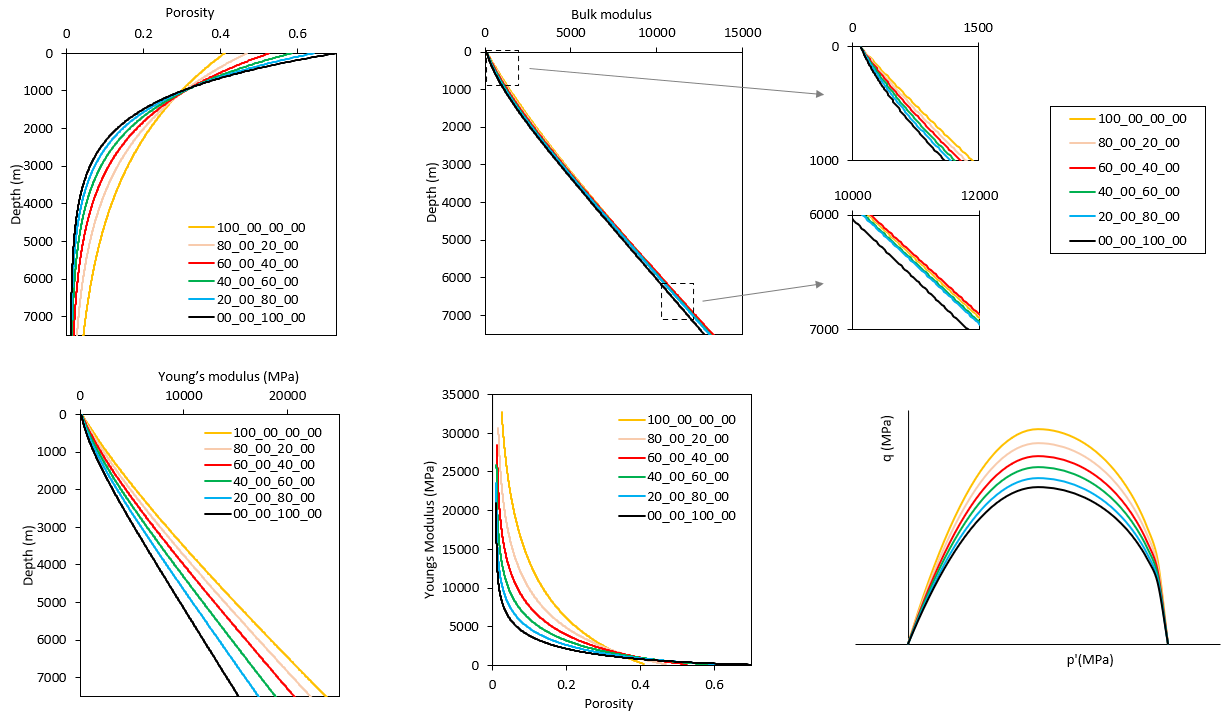

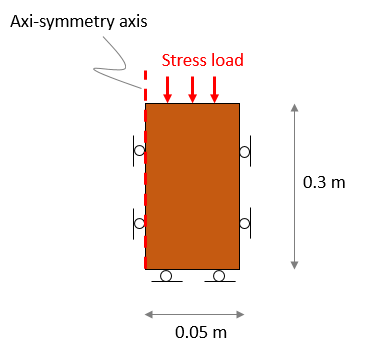

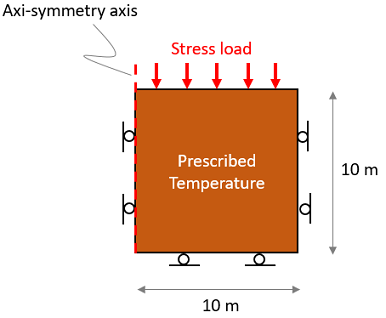

•SR4 material hardening calibration to user-defined hardening model •Provision of facies mixture-based material database spreadsheet and step by step description for user-derivation •Axi-symmetric single element oedometer test (geomechanical) •Uniaxial column consolidation test (coupled THM) |

Mechanical properties for different component % of Sandstone, Siltstone, Shale, Carbonate (Ss_Si_Sh_Ca) |

|

Mechanical (2D) and Coupled THM (2D) |

|

|

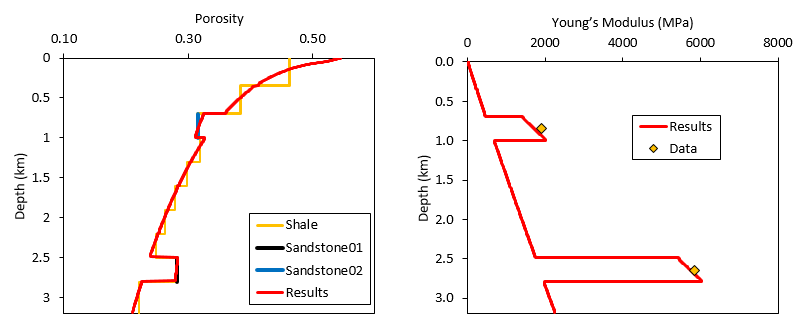

•Simplified input of data in the form of Athy-type models to characterise mechanical compaction •Automated hardening data generation |

Validated results generated using the mechanical compaction models |

|

Mechanical (2D) |

|

|

|

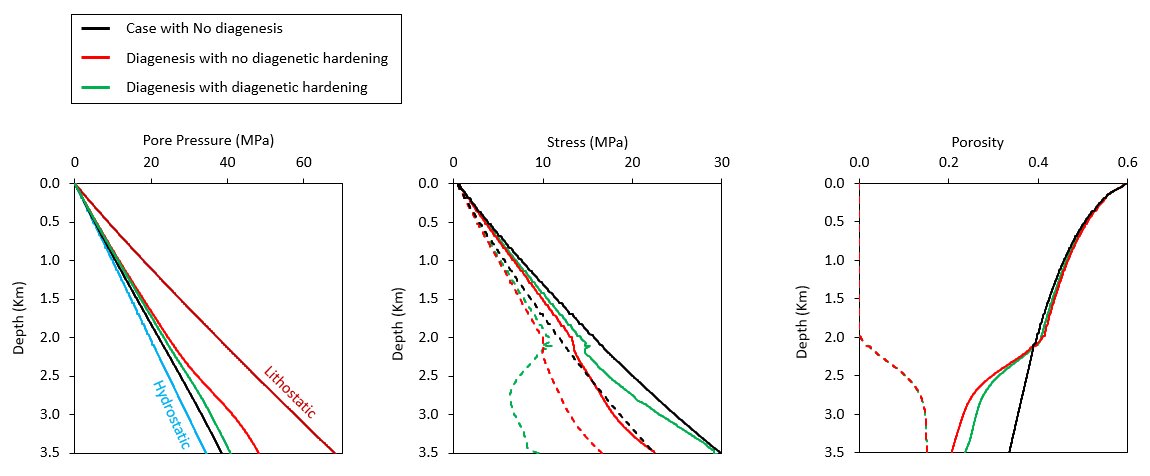

•Diagenesis model and behaviour

|

|

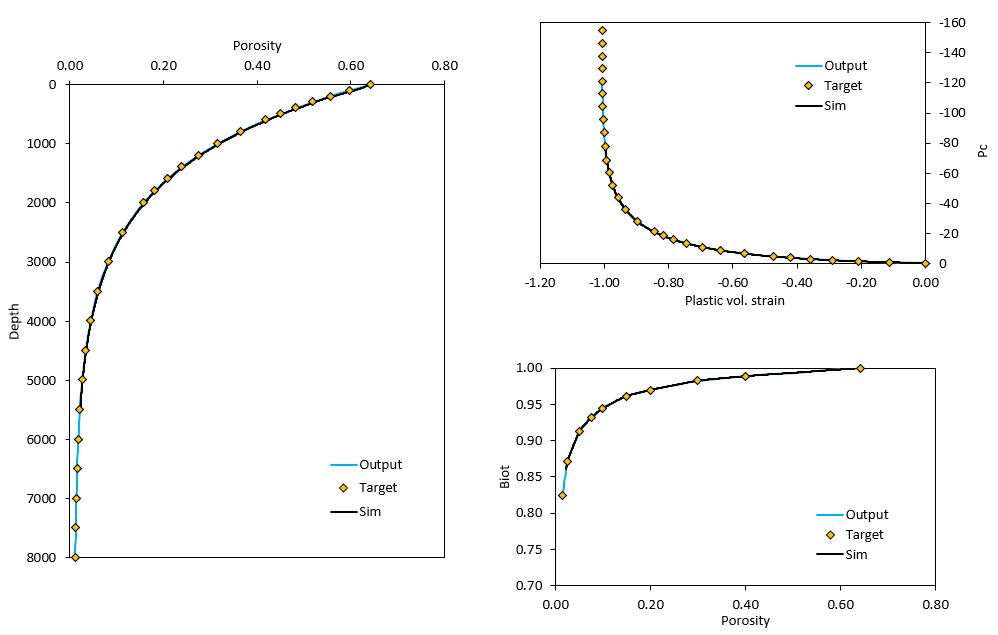

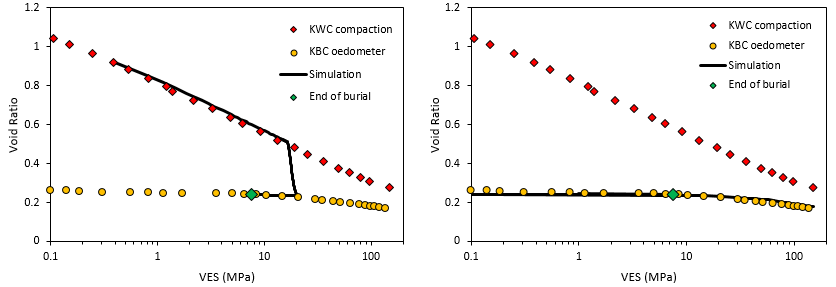

•Calibration of diagenesis law for Kimmeridge Clay and Berea Sandstone •Axi-symmetric single element oedometer test/burial history simulation |

Axi-symmetric single element: Oedometer test (left), Burial history simulation (right)

Results vs geomechanical tests. Simulation of burial history (left). Additional unloading/reloading (right) |

|

Mat_003 Continuum Fracture Model (PVC test on a fractured specimen) |

Coupled HM (3D) |

|

•Case1a Poroelastic simulation •Case1b Poro-elasto-plastic (SR4) simulation •Case 2a (poroelastic) and Case 2b (SR4) with 2 sets of fractures |

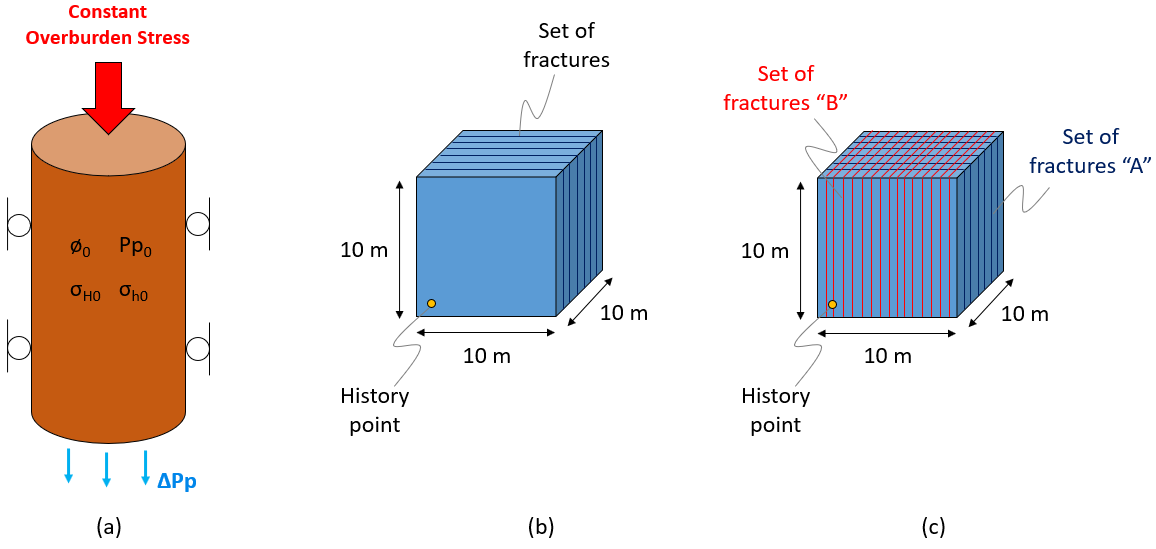

•Pore Volume Compressibility (PVC) test •Poroelastic / with SR4 plasticity materials •Single hex element continuum fracture model with one/two fracture sets |

(a) Schematic of PVC test, (b) Model with 1 fracture set (Case 1), (c) with 2 fracture sets (Case 2) |

Mechanical (2D) |

|

|

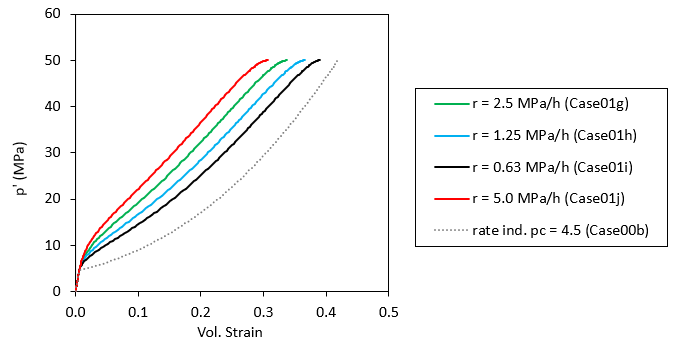

•Case02 Power law model with accelerated creep at high deviatoric stresses |

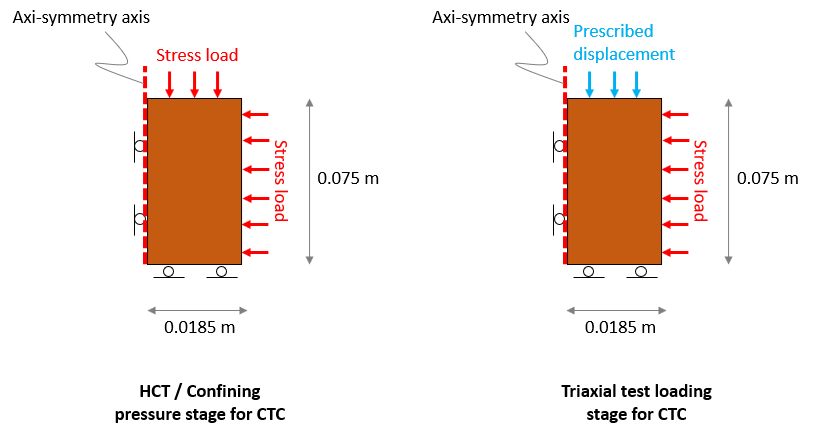

•SR3 plasticity model with simple Power law creep/Power law with accelerated creep at high q •Hydraulic Compression Tests (HCT) and Triaxial tests (CTC) at different loading rates |

|