MEM and Wellbore modelling

INDEX

Title |

Analysis Type - Features List / Utility |

Model |

Workflow for Material Earth Models (MEMs) |

||

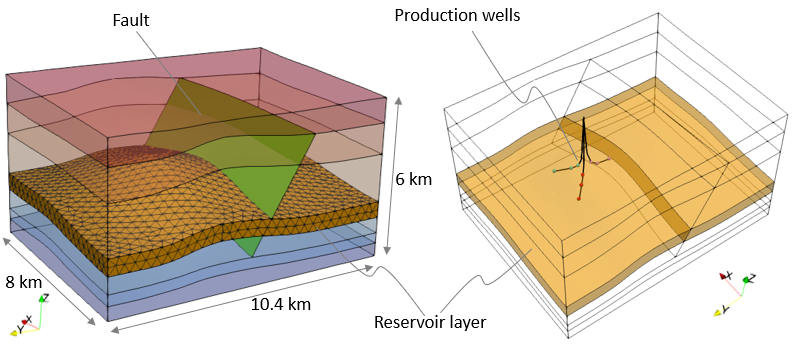

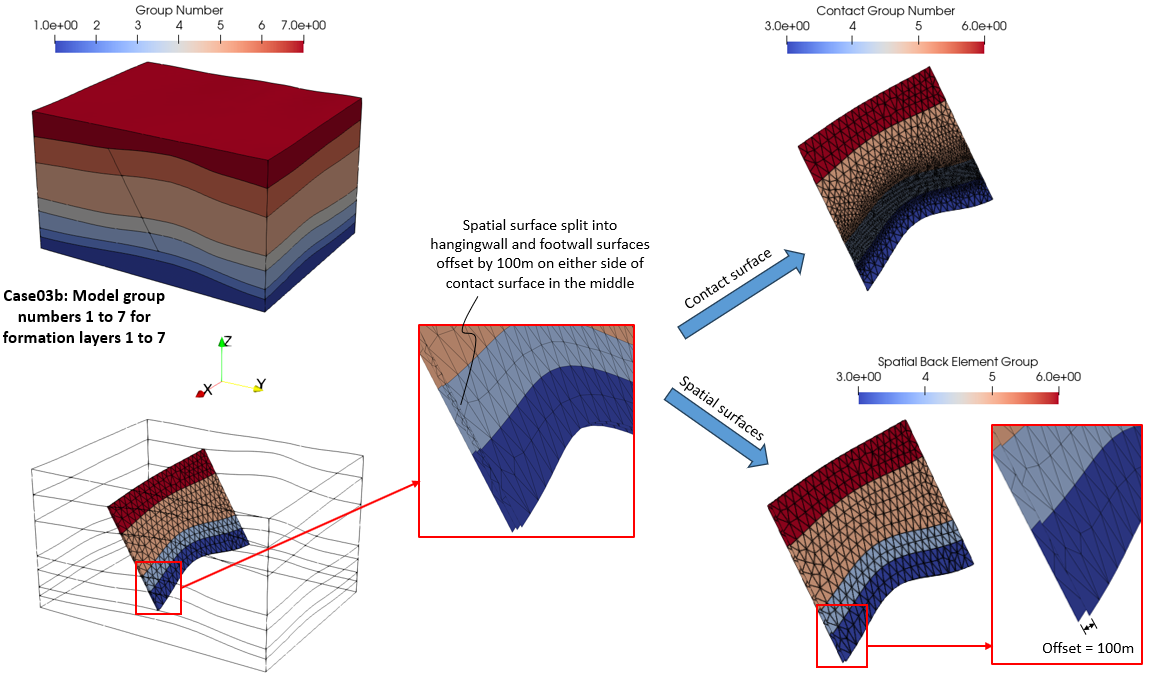

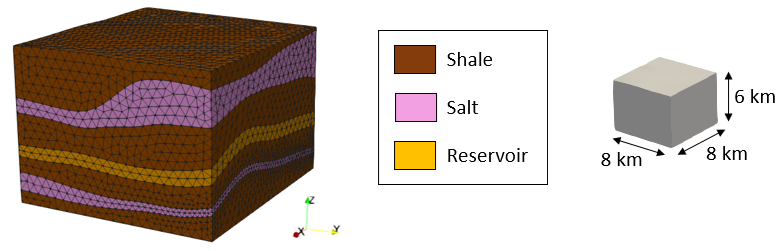

Mechanical (3D) / Coupled HM (3D) |

|

|

|

•Various geostatic initialization phases (gravity, tectonic, contact release, constitutive release) •Production simulation •Mechanical contact •Initial spatial grid data and spatial boundary |

|

•Case 1b Reservoir Poro-elasticity defined via Spatial_table |

•Young's modulus - porosity dependent spatial table |

|

•Geostatic initialization stages (gravity and tectonic) via implicit solver •Restart data |

||

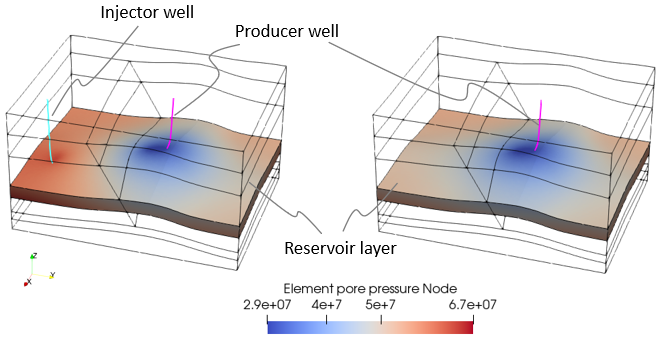

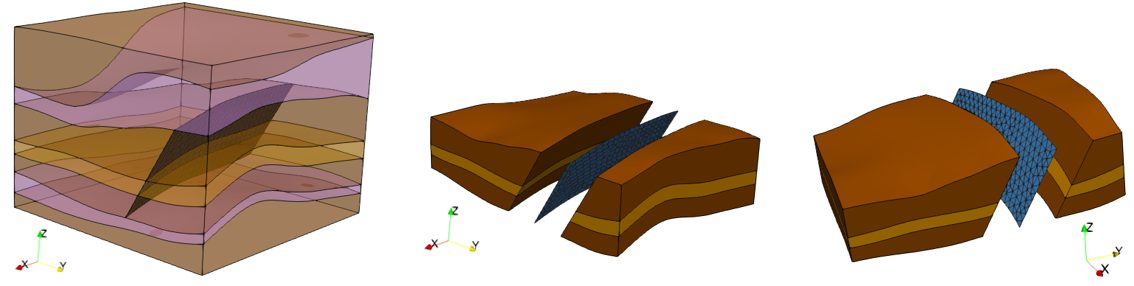

•Case 3a HM Coupled (High Perm Fault) •Case 3b HM Coupled (Low Perm Fault)

|

•Coupled HM simulation •Water level •Well element for producer well •High/Low perm contact fluid flow •Initial spatial grid data and spatial boundary |

|

•As Case 3a •Well element for producer and injector wells |

||

•As Case 4 •De-activation of porous flow groups |

||

•As Case 4 and Case04b respectively •Full implicit solver utilized for coupled hydro-mechanical solution •Node-node contact algorithm |

||

•Case 5 Mapping of Results to Spatial Surface and Output to Plot File |

•Read results plot file and output to new plot file •Mapping of results to imported Spatial surface definition |

|

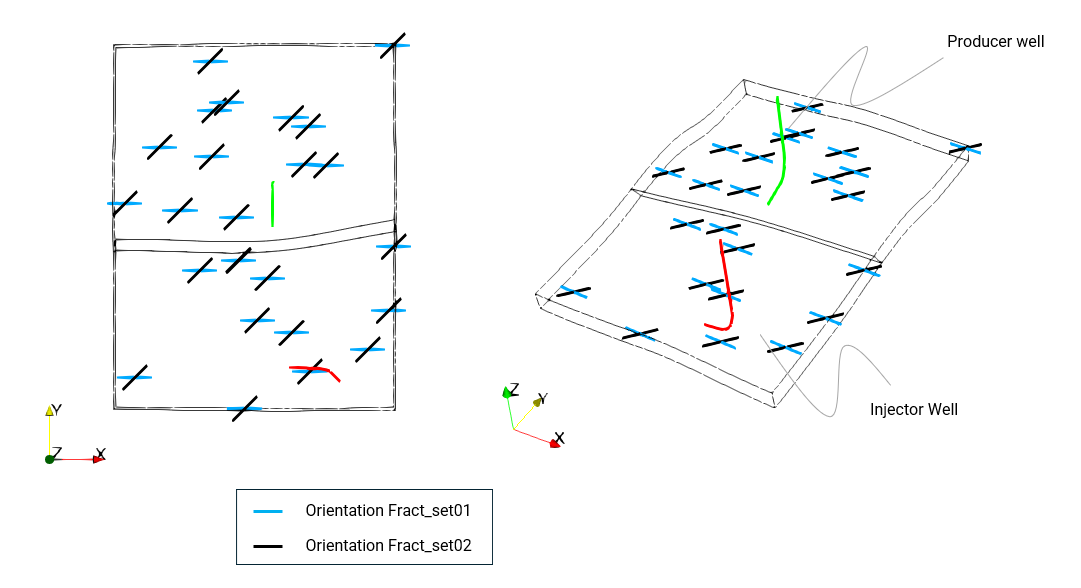

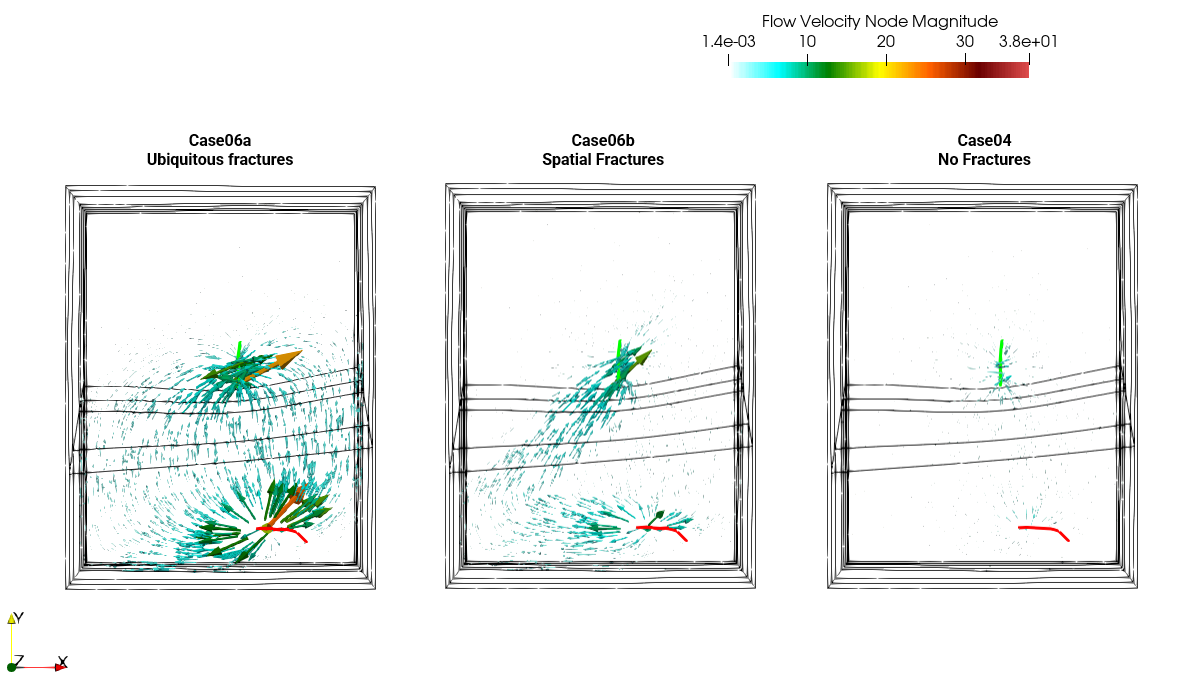

•Case 6 Reservoir with Fractures oCase06a - Ubiquitous fractures with homogeneous properties with fracture spacing of 5m oCase06b - Two corridors of fractures with spatial definition of fracture spacing ranging from 25m to 75m |

•Inclusion of embedded fractures in the reservoir and their influence on pore pressure distribution and flow |

|

Mechanical (3D) |

|

|

•Salt layers modelled via Herschel-Bulkley viscoplastic material •Various time unit updates via salt material constant K |

|

|

•Case 2 Faulted Case (Not available yet) |

•Faulted model with contact |

|

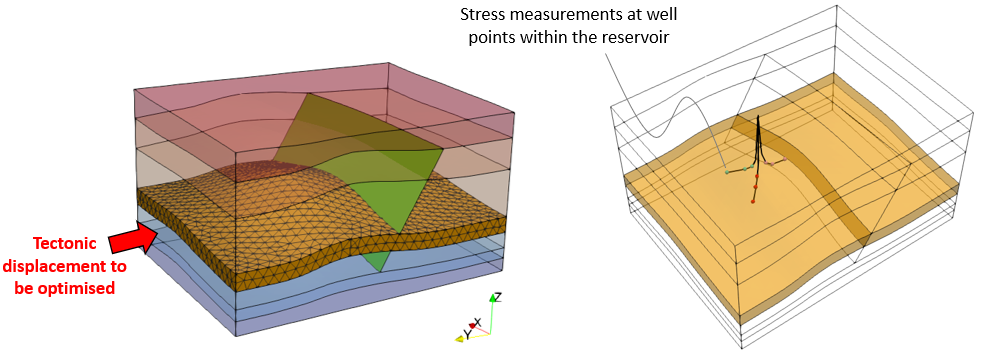

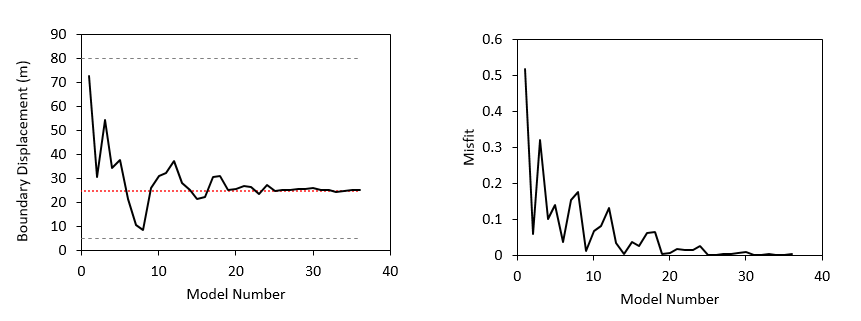

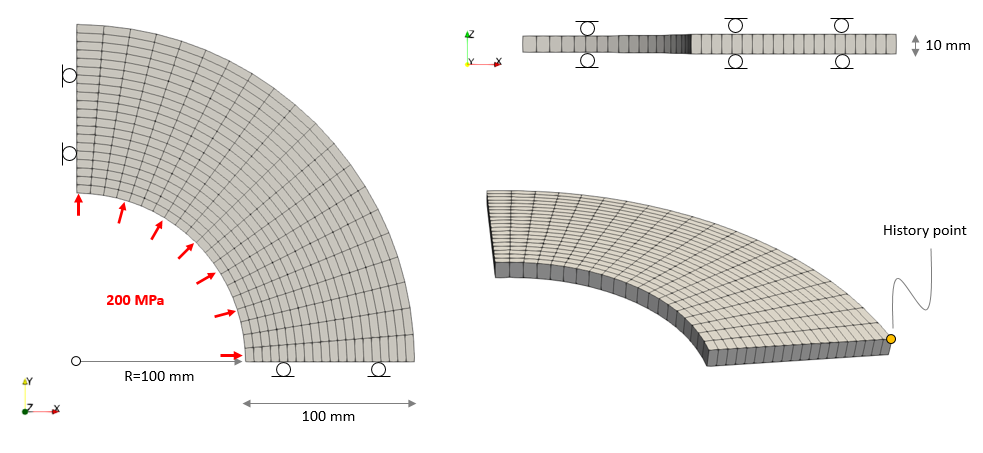

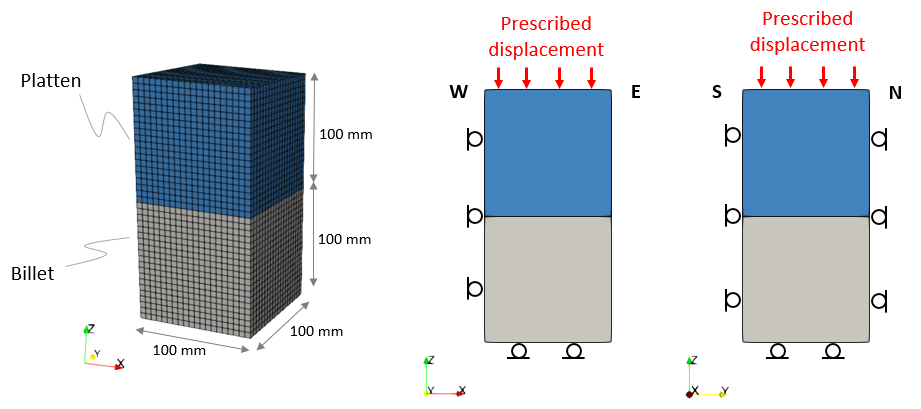

MEM_003 Boundary Optimisation and Super Element approach within the MEM Workflow |

Mechanical (3D) using ParaGeoInv |

|

•Case 2 Boundary optimisation using the Super Element approach (Currently unavailable) |

•Inverse analysis for initialisation stages using ParaGeoInv •Usage of Super element |

|

Implicit Solver |

||

Mechanical (3D) |

|

|

•Implicit solver |

|

|

Super Element (Currently unavailable) |

||

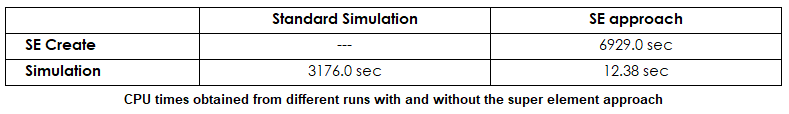

SuEl_001 Super Element Workflow |

Mechanical (3D) |

|

•Case 1 Workflow Example oStep 1 Create the Super Element oStep 2 Use the Super Element oStep 2b Use an Reflate the Super Element •Case 2 Usage of Coupled Freedoms |

•Super element workflow •Implicit solver •Coupled freedoms |

|

Wellbore Models |

||

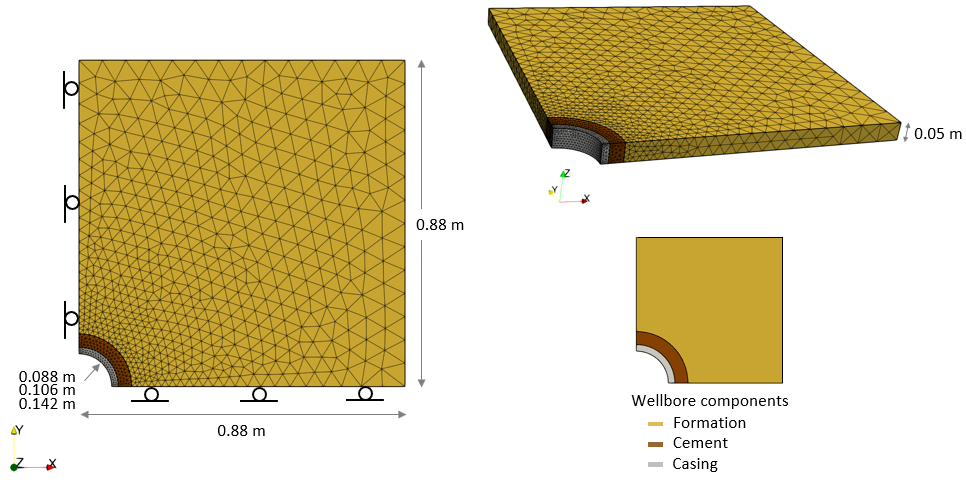

Coupled THM (3D) |

|

|

•Case01 Time-dependent Cement Hardening with Diagenetic Shrinkage |

•Coupled THM simulation •Deactivated porous flow in casing and cement •Contact between wellbore components •Time-dependent cement hardening material with increased yield strength •Cement hardening with diagenetic reaction resulting in volume shrinkage •Usage of transient time step growth in solution control |

|

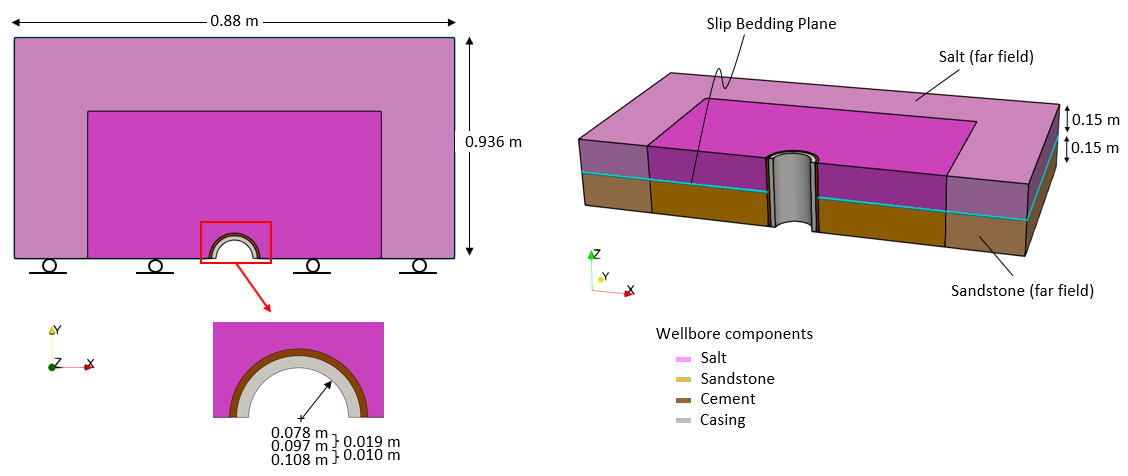

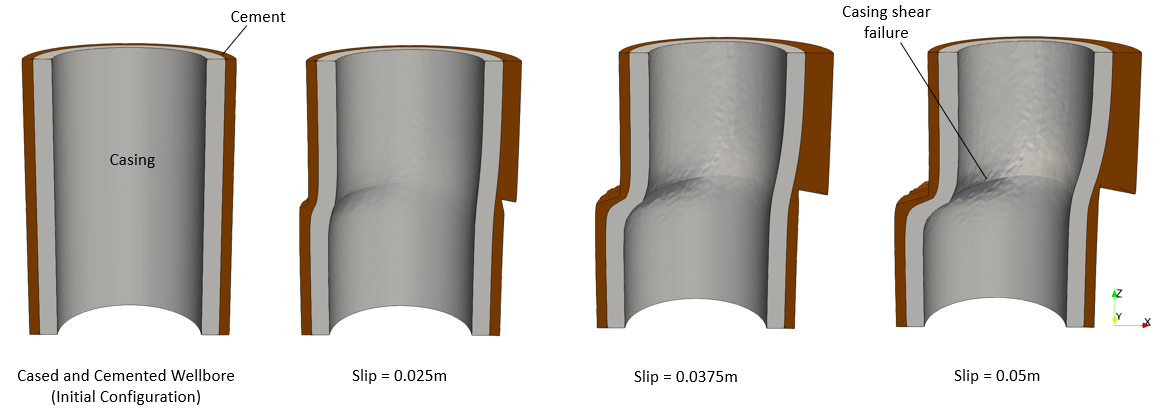

Wellbore_002 Casing Collapse due to Shear at Salt/Sandstone Bedding Plane |

Mechanical (3D) |

|

|

•Contact between salt/sandstone bedding plane •Large bedding plane slip (shear) causing casing collapse •Salt with Herschel-Bulkley viscoplastic material |

|